Search keywords:

product name, product type, model number,

test method, manufacturer, technique, application

General Air Filter Test System

BACKStandards:

ISO 16890-FDIS, EN 779 and ASHRAE 52.2

Applications:

Product Information:

The test rig has been developed for air filter testing according to standards ISO 16890-FDIS, EN 779 and ASHRAE 52.2. The following parameters of the filter under test can be detected:

● Differential pressure

● Dust holding capacity

● Efficiency after different dust loading phases and average efficiency

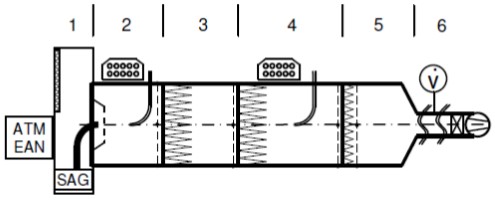

The filter samples can be easily installed into the rotatable and movable duct sections. A conditioned and filtrated air flow is loaded with particles. In this way information about the increasing differential pressure and the efficiency of the filters will be obtained. With these results the filter samples can be classified. The test duct is divided into 6 duct sections and constructed airproof. By dint of a filter the air is sucked in at duct section 1 and blown out behind the blower (see schematic). The pressure measuring facilities in duct section 2...5 are used for determining the differential pressure of the respective particular filter. The measurement of the pressure drop between the final filter and the protection filter is available as an option.

Features:

◆ Measurements according to standards ISO 16890-FDIS, EN 779 and ASHRAE 52.2 possible

◆ Rotatable and movable duct sections● Differential pressure

● Dust holding capacity

● Efficiency after different dust loading phases and average efficiency

The filter samples can be easily installed into the rotatable and movable duct sections. A conditioned and filtrated air flow is loaded with particles. In this way information about the increasing differential pressure and the efficiency of the filters will be obtained. With these results the filter samples can be classified. The test duct is divided into 6 duct sections and constructed airproof. By dint of a filter the air is sucked in at duct section 1 and blown out behind the blower (see schematic). The pressure measuring facilities in duct section 2...5 are used for determining the differential pressure of the respective particular filter. The measurement of the pressure drop between the final filter and the protection filter is available as an option.

Features:

◆ Measurements according to standards ISO 16890-FDIS, EN 779 and ASHRAE 52.2 possible

◆ Universal filter holding system

◆ Online weighing of dust feeder

◆ Additional test dust feeder for ISO 12103 test dust available

◆ High level of automation, mostly automated test runs with complete operator guiding through all tests, data handling and protocols

◆ Safety functions realized in a PLC

Components:

◆ Inlet air conditioning with particle filter (min. H 13)

◆ DEHS Aerosol Generator for filtration efficiency measurement and discharging of the filters to be tested, neutralization by means of the electrostatic aerosol neutralizer

◆ ASHRAE dust generator for dust loading; Online-weighing, mixing orifice

◆ Test duct sections made from stainless steel, quadratic shaped cross section (610 x 610 mm), with window and backup filter

◆ Particle measurement at the same time with 2 optical particle counters (0.2…10 μm, 16 particle size classes)

◆ Universal filter holding system for bag filters and cassette filters, filter cartridges as well as flat sheet filter media

◆ Sensors for measurement of differential pressure, air flow rate, temperature and relative air humidity

◆ Flow rate unit with radial blower, controlled by frequency inverter and throttle flap; wide flow rate

Dust sections:

1 Mixing chamber 2 Measuring chamber of the raw gas

3 Filter sample chamber 4 Measuring chamber of the clean gas and the final filter

5 Duct section with protection filter 6 Volume flow rate measuring system

Technical Parameters:

| Items | Parameters |

| Flow rate | 600 to 6000 m³/h |

| Differential pressure | Max. 2000 Pa |

| Test aerosol | DEHS, KCl |

| Loading dust | ASHRAE test dust, ISO 12103-A2 (fine) and ISO 12103-A4 (coarse) |

| Filter samples | Pocket and cassette filters with max. dimensions 610 x 610 mm Optional: Filter cartridges, max. 400 mm diameter, length of max. 1.5 m Flat sheet filter media, max. surface 1 m² |

| Compressed air supply | Min. 5 bar (17 m³/h) |

| Power supply | 3 x 400 V AC; 125 A; 50 Hz |