Search keywords:

product name, product type, model number,

test method, manufacturer, technique, application

Filter Tester G4500

BACKStandards:

ISO 11155-1 / DIN 71460-1 (cabin air filters), ISO 5011 (engine pre-air filters), EN779/ASHRAE 52.2 (room air filters), EN 1822-3 (HEPA filters), CEN EN 143

Applications:

Testing of filter media and small filter elements in product development and during production monitoring.

Product Information:

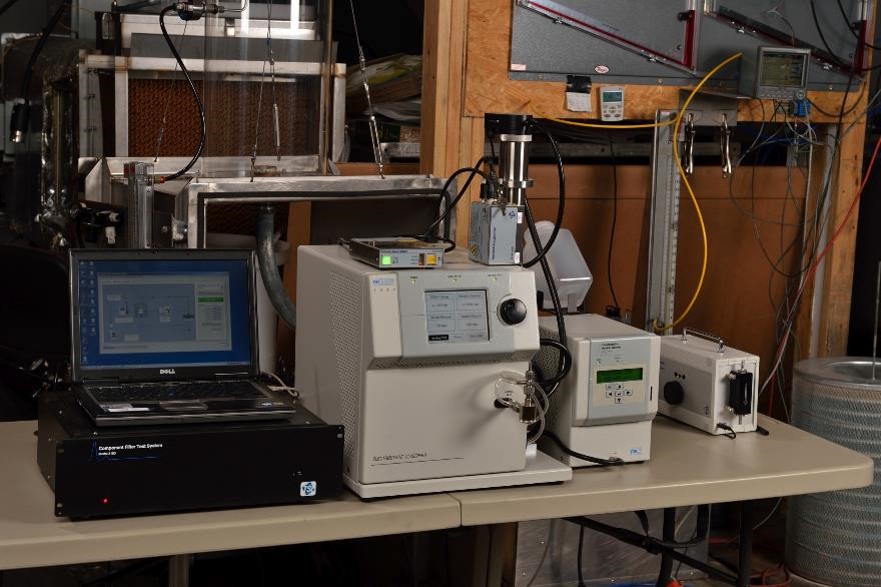

G4500 with two Promo® aerosol spectrometers for simultaneous determination of fraction separation efficiency

The MFP filter test rig is a modular filter testing system for flat filter media and small mini-filters. This enables you to determine the pressure loss curve on the medium without a dust coating, fraction separation efficiency, or burden and fraction separation efficiency during application of the burden and the gravimetric separation efficiency within shortest times – reliably and therefore cost-effectively. The G4500 operates in suction mode. This ensures a particularly uniform formation of the dust cake even at high inflow speeds. With the new FTControl test rig software of the G4500, the aerosol spectrometer Promo®1000/2000 is used for clear and reliable determination of the aerosol concentration and particle size and therefore clear determination of the fraction separation efficiency.The use of one aerosol spectrometer Promo® 1000/2000 in raw gas and one in clean gas within simultaneous operation offers the following advantages: Fully-automatic simultaneous measurement of fraction separation efficiency Faster determination of the beginning fraction separation efficiency because of bisection of the testing time for the fraction seperation efficiency. Higher temporal resolution for the measurement of fraction seperation efficiency during loading. Using the testing system for very high and very low aerosol concentrations. The largely automated setup of the test sequence in conjunction with the clearly defined individual components and the individually adjustable sequence programs of the filter test software FTControl combine to deliver the high reliability of our measurement results.

Our quality in detail

Structure:

1. Variable aerosol generation Thanks to the use of different dispersers for dusts, KCl/NaCl, DEHS etc.; shortened measurement times are possible e.g. through increased dust concentration

2. Corona discharge (optional): Adjustable ion stream for different mass flows. Mixed air, adjustable for inflow speeds from 0.05 to 1 m/s. Optional: Transient inflow.

3. Light scattering spectrometer Promo® 1000/2000 for clear particle measurements in high concentrations of up to 5000 mg/m3 (SAE Fine) and low concentrations for the determination of the initial fraction separation efficiency

4. Mobile pneumatic filter holder for fast removal and loading of the test rig.

5. Gravimetric filter holder for simple and fast evaluation of the gravimetric separation efficiency.

6. Raw gas sensor

7. Clean gas sensor

Features:

Simultaneous particle measurement in the raw gas and clean gas

Particle size measurements from 0.2 – 40 µm

Measurement of Cn max= 106 particles/cm3 without dilution

Internationally comparable measurement results

Widespread distribution of the measurement system

High reproducibility of the testing method

Easy use of different test aerosols, e.g. SAE Fine and Coarse, NaCl/KCl, DEHS

Highest raw gas concentrations of up to > 1000 mg/m3 (ISO Fine) or > 5000 mg/m3 (ISO Coarse) with measurement of the fraction separation efficiency for burden tests

Flexible filter test software FTControl

Sequence programs for pressure loss measurements, measurements of fraction separation efficiency and burden measurements

Easy to operate, even untrained personnel can be instructed quickly in the use of the equipment

Short set-up times

Cleaning and calibration can be performed autonomously by the customer

Easy use of the measurement technology components – even in other applications

Mobile setup, easy to move on castors

Reliable operation

Validation of the clear function of individual components and the overall system during pre-delivery acceptance testing and upon delivery

Low-maintenance

The unit will reduce your operating costs

Technical Parameters:

| Items | Parameters |

| Measurement range | 0.2– 40 µm |

| Volume flow | 1 – 35 m³/h (pressurized operation) |

| Power supply | 115/230 V, 50/60 Hz |

| Dimensions | 600 • 1800 • 900 mm (W • H • D) |

| Inflow velocity | 5 – 100 cm/s |

| Differential pressure measurement | 0 – 5000 Pa |

| Test area of the medium | 100 cm² |

| Aerosol | Dusts(e.g. SAE dust),salt(e.g. NaCl, KCl ),liquid aerosol(e.g. DEHS) |

| Aerosol concentration | Undiluted refined SAE concentration up to 1000 mg/m3 (ISO A2 Fine) |

| Compressed air supply | 6 – 8 barg |