Search keywords:

product name, product type, model number,

test method, manufacturer, technique, application

Single Burning Item

BACKStandards:

GB/T 20284, EN13823

Applications:

The Single Burning Item (SBI), is a method of test for determining the reaction to fire behaviour of building products (excluding floorings) when exposed to the thermal attack by a single burning item

Product Information:

Features:

1. The core parts of the SBI are imported components, such as gas analysis instrumentation of CO2, O2, etc.

2. The SBI used in Ministry of Public Security of Sichuan fire research institute is also our products, used well so far.

3. Operation Interface and the properties are equivalent to the FTT, even more superior to it in some ways.

4. Convenient and fast in maintenance, the replacement of spare parts is 50% ~ 70% lower than FTT, therefore no trouble with maintenance.

5. Imported integrated control cabinet. (Please contact us to acquire specific list of imported accessories).

Technical Parameters:

1. Using 16-bit high-precision card, and computer controlled with WINDOWS XP, with a character of reasonable structure, stable performance.

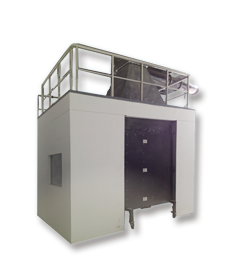

2. The item includes combustion chamber, control cabin, trolley, exhaust pipe, Data acquisition and analysis software, gas supply and control device.

3. Ignition source, burner of 31KW propane fuelled sand-box (side length 250mm, height 80mm) located on the corner of trolley.

4. With comprehensive sampling area in the exhaust duct to place sensors and sampling tube, and the specimen is mounted on a trolley.

5. Combustion chamber with height of 2.4m high and an area of 3m×3m, in which the test perform, with the gas-collecting hood and exhaust pipes collected to sampling pipe at the top of the chamber, air could get in and out of it through the place below the trolley.

6. Heat release and combustion products of test samples in the testing process discharged from the exhaust pipes.

7. O2 measuring range: 0-25%, linearity <±0.1%.

8. CO2 measuring range: 0-10%, repeatability <±1%.

9. High precision pressure regulating valve to regulate the pressure as required by the standards.

10. Glass rotameter to regulate the flow of burner.

Data acquisition and analysis system can collect and record test data, such as the concentration of O2 and CO, temperature, smoke density, heat release rate, mass loss, etc. which can be stored.(we have detailed technical parameters that may help to figure out any of your question on SBI, please contact us for details.)