NewsInformation Center

What are the standards for zipper testing?

2023/06/26

Zipper is a commonly used connecting device, widely used in clothing, bags, shoes and hats, household goods and other industries. In order to guarantee the quality and performance of zippers, various tests are required. Some common zipper test standards are introduced below.

1. Zipper pull test

Pull testing is a method of testing the strength and durability of zippers. Test standards usually vary by industry and product. For example, in the garment industry, commonly used testing standards include GB/T 2428-1998 "Test Method for Tensile Strength of Zipper" and GB/T 10454-2000 "Test Method for Durability of Zipper".

During the test, the zipper needs to be fixed on the testing machine, and then a pulling force is applied at a certain speed until the zipper breaks or the pulling force reaches the set value. The test results usually include data such as maximum tensile force, breaking force and tensile deformation.

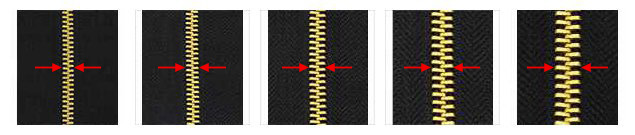

2. Zipper sliding test

The slide test is a method of testing the smoothness of opening and closing and abrasion resistance of zippers. Test standards usually vary by industry and product. For example, in the luggage industry, commonly used testing standards include QB/T 2171-2004 "Test Method for Zippers" and GB/T 22796-2009 "Test Method for Zippers for Luggage and Bags".

During the test, the zipper needs to be fixed on the testing machine, and then opened and closed at a certain speed, and the opening and closing force and the number of opening and closing times are recorded. Test results usually include data such as opening and closing force, number of opening and closing, and coefficient of friction.

3. Zipper Compatibility Test

Compatibility testing is a method of testing the compatibility of zippers with various materials. Test standards usually vary by industry and product. For example, in the household products industry, commonly used testing standards include ISO 105 G02-1994 "Fiber and Plastic Compatibility Test" and ASTM D543-06 "Plastic Material Compatibility Test Method" and so on.

During the test, it is necessary to contact the zipper with different materials, such as fabric, leather, plastic, etc., and then observe whether discoloration, deformation, cracks, etc. occur. Test results usually vary according to different test methods.

Salt spray test is a method to test the anti-corrosion performance of zippers. Test standards usually vary by industry and product. For example, in the automotive industry, commonly used testing standards include ISO 9227-2017 "Corrosion Resistance Test. Salt Spray Test" and ASTM B117-16 "Salt Spray Corrosion Resistance Test Method", etc.

During the test, the zipper needs to be placed in a salt spray test chamber and tested at a certain temperature and humidity. The test time usually ranges from 24 hours to 1000 hours. Test results usually vary according to different test methods.

5. Environmental testing

Environmental testing is a way to test whether a zipper meets environmental requirements. Test standards usually vary by industry and product. For example, in the EU market, commonly used testing standards include REACH and RoHS.

During the testing process, it is necessary to conduct chemical composition analysis and heavy metal content testing on the zipper to determine whether the zipper meets environmental protection requirements. Test results usually vary according to different test methods.

The above are some common zipper test standards, I hope it will be helpful to you.

Previous: Which industries need to use xenon lamp aging test chamber?

N e x t : What are the 3 types of fabric testing?