NewsInformation Center

What's the testing wear resistance and pilling performance methods of materials

2023/07/11

When it comes to testing materials for abrasion resistance and pilling properties, there are a variety of methods and equipment to choose from. Below I will introduce some commonly used methods and equipment, as well as their characteristics and applications.

1. Abrasion Tester:

Abrasion testing machines are used to evaluate the wear resistance of materials. Common wear test methods include sliding wear, scratch wear, and reciprocating wear. These tests usually use standardized test specimens and wear heads to simulate the wear conditions in actual use by applying certain forces and motions. Abrasion testing machine can quantitatively measure the wear amount and wear rate of materials, so as to evaluate the wear resistance of materials.

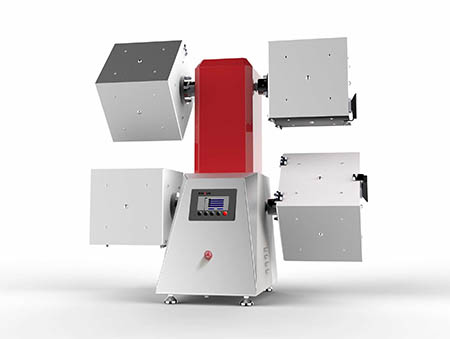

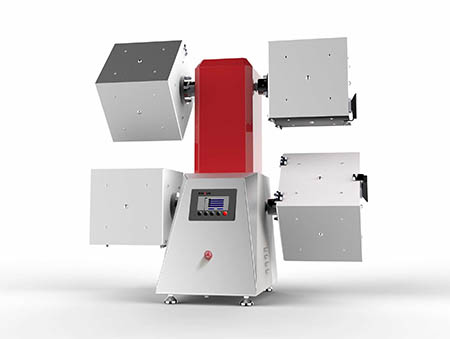

2. Pilling Tester:

The pilling test machine is used to evaluate the pilling performance of materials such as fabrics. The device observes and evaluates the pilling of the fabric surface by simulating the friction and wear of the fabric surface. The pilling test usually uses a standardized sample and a friction head to undergo a certain reciprocating motion and friction to produce a pilling phenomenon. The pilling test machine can quantitatively measure the pilling degree and pilling density, so as to evaluate the pilling performance of the material.

3. Manual wear test:

Manual wear test is a simple and economical method to evaluate the wear resistance and pilling performance of materials through manual operation and observation. For example, tools such as artificial abrasives, sandpaper, brushes, etc. can be used to rub and wear the material, followed by visual inspection or microscopic observation to evaluate wear and pilling. The advantage of this method is its low cost, but the results may be affected by operator subjective factors.

4. Other test methods:

There are a number of other test methods that can be used to evaluate a material's abrasion resistance and pilling properties. For example, optical microscopy, scanning electron microscopy (SEM), etc. can be used to observe the morphology and microstructure changes of the material surface. In addition, methods such as tensile tests and coefficient of friction tests can be used to evaluate the performance of materials.

To sum up, the wear resistance and pilling performance of materials can be evaluated by using methods such as wear tester, pilling tester, and artificial wear test, combined with observation methods such as optical microscope and SEM. Selecting the appropriate test method depends on the specific material and testing needs.

Previous: UV aging test: Can you recommend any specific control samples to use?

N e x t : Is there a recommended frequency for calibrating the Random Tumble Pilling Teste