NewsInformation Center

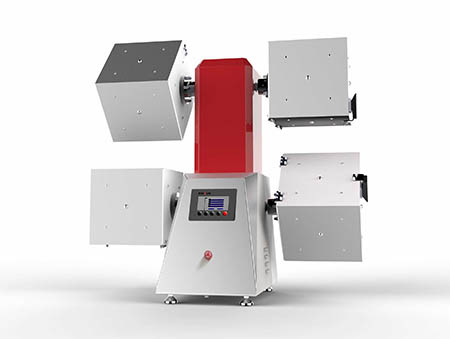

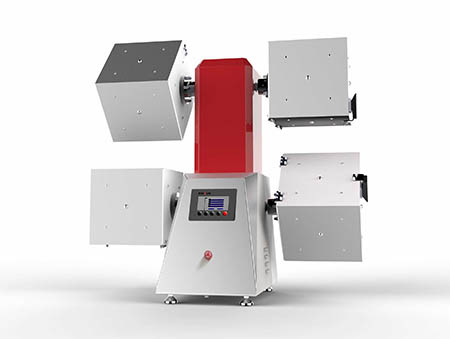

What kind of experiment is Textile Pilling Tester mainly used for?

2023/07/11

Textile Pilling Tester is an instrument used to evaluate the pilling and pilling properties of fabrics. It simulates the friction and wear of fabrics during use, and provides information about fabric durability and appearance quality by quantitatively evaluating the degree of fuzzing and pilling of fabrics. The following are the experiments that the pilling rating box is mainly used for:

1. Fuzz test:

The fuzz test is to evaluate the degree of hairiness on the fiber surface of the fabric during use. In a pilling chamber, a fabric sample is rubbed against a standardized fabric or metal surface, simulating the wear and tear of the fabric when it comes into contact with other materials. By observing and counting the number and density of hairiness on the surface of the fabric, the fluff performance of the fabric can be evaluated.

2. Pilling test:

The pilling test is to evaluate the degree of small spherical fiber agglomeration on the surface of the fabric during use. In a pilling chamber, fabric samples are rubbed against standardized fabric or metal balls, simulating the wear and tear of fabrics in contact with other materials. The pilling performance of the fabric can be evaluated by observing and counting the number and density of small spherical agglomerates on the surface of the fabric.

3. Rating and Classification:

The Pilling Rating Box can also rate and classify fabrics according to the degree of pilling and pilling. Grading generally uses a standardized scoring system to classify fabrics into grades or grades based on the number, size and density of hairiness and nodular agglomerations on the surface of the fabric. These ratings and classifications help manufacturers, suppliers and consumers understand the quality and durability of fabrics so they can make appropriate choices.

4. Quality control and product development:

Pilling bins play an important quality control role in fabric production. Manufacturers can use this instrument to monitor and control the degree of fabric fuzzing and pilling, ensuring that products meet quality standards and customer requirements. In addition, the pilling rating box can also be used in the product development stage to help designers and engineers select the appropriate fibers, fabric construction and surface treatment to improve the durability and appearance quality of the fabric.

In summary, the pilling rating box is mainly used to simulate the friction and wear of fabrics during use, and provide information about fabric durability and appearance quality by evaluating the degree of pilling and pilling. It plays an important role in fabric production and product development, helping manufacturers control quality, evaluate product performance, and meet consumer needs and expectations.

Previous: What are some common conditions that may affect fabric pilling testing results?

N e x t : Are there any alternative methods for evaluating fabric pilling resistance?