NewsInformation Center

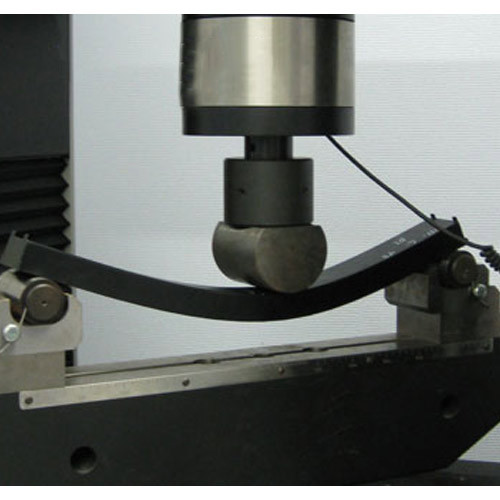

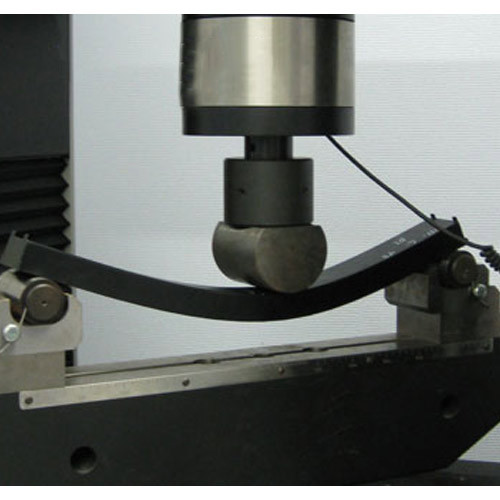

What are the safety considerations when using rubber testing equipment?

2023/07/12

Rubber testing equipment is a tool used to evaluate the properties and quality of rubber materials. When using rubber testing equipment, it is important to pay attention to the following common safety precautions to ensure personal safety:

1. Follow the equipment's operating manual:

Carefully read and understand the operating manual of the rubber testing equipment and follow the operating instructions and safety recommendations provided by the equipment manufacturer.

2. Wear personal protective equipment:

Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, earplugs or ear muffs, protective clothing, etc., as required by the specific equipment. This equipment protects you from potential hazards and injuries.

3. Operate equipment safely:

Operate the RUBBER TESTING EQUIPMENT correctly and make sure you understand how the equipment works and how to operate it. Follow the correct operating sequence and procedures to avoid incorrect use or operation.

4. avoid overloading:

Make sure not to exceed the rated operating range and load capacity of the equipment. Avoid applying excessive force or strain that may damage the equipment or cause accidents.

5. Check the equipment regularly:

Check the condition and function of the RUBBER TESTING EQUIPMENT before use. Make sure that the equipment is not damaged, loose, broken or otherwise a safety hazard. If any problems are found, repair or replace it promptly.

6. Prevent splashing or spraying of samples:

When performing rubber testing, especially at high pressures or high speeds, make sure that samples or parts of the equipment do not splash or spray. Take appropriate measures, such as using safety fixtures or protective covers, to prevent potential injury.

7. Avoid direct contact with hot surfaces:

Some rubber testing equipment may have hot surfaces or heating elements. Avoid direct contact with hot surfaces when using this equipment to avoid burns. Use insulated gloves or tools to handle hot samples or hot surfaces.

8. Handle chemicals properly:

If chemicals are involved in testing, proper chemical handling and storage procedures must be followed. Know the nature, hazards, and proper handling of chemicals and take appropriate measures such as wearing gloves, goggles, and ventilation.

9. periodic maintenance and calibration:

Periodic maintenance and calibration of RUBBER TESTING EQUIPMENT to ensure performance and safety. Follow the equipment manufacturer's maintenance recommendations and contact a service professional for maintenance and calibration as needed.

10. training and qualifications:

Ensure that operators are properly trained and have the skills and knowledge required to operate the RUBBER TESTING EQUIPMENT. Follow applicable safety standards and regulations, and ensure that only trained and authorized personnel operate the equipment.

These safety precautions can help you stay safe and minimize the risk of accidents and injuries when using rubber testing equipment. Remember, safety is always the primary consideration and should always take precedence over any testing or operation.

Previous: Comparing Gas Fume Color fastness Testing with Other Colorfastness Tests

N e x t : How do I select the right Steaming Cylinder for a specific test material?