NewsInformation Center

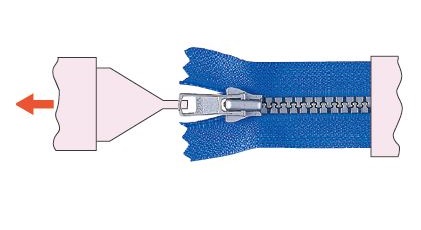

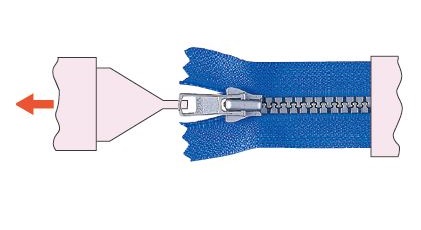

Common Challenges in Zipper Strength Testing and Solutions

2023/07/14

Zipper strength testing is one of the key tests to evaluate the durability and load-bearing capacity of zippers, but there are some common problems that may be encountered during the testing process. Below are some common problems and their solutions to help you better perform zipper strength testing.

1. Fixture selection problem:

Selecting a suitable fixture is an important part of the zipper strength test. Fixtures should be designed to securely hold the sample and prevent the sample from slipping or deforming. If the fixture is not selected properly, it may lead to inaccurate test results. The solution is to select the appropriate clamp according to the size and shape of the zipper, and ensure that the contact surface between the clamp and the sample is sufficient.

2. Sample preparation issues:

The preparation of zipper samples requires attention to some key details. For example, the length of the sample, the way it is fixed and the state of preparation, etc. will all have an impact on the test results. The solution is to prepare samples according to the requirements of the test standards and ensure that the sample preparation process complies with the standards. In addition, samples should be randomly selected to ensure representativeness of test results.

3. Tension speed problem:

The tension speed in the zipper strength test is an important parameter, which can affect the accuracy of the test results. Too fast or too slow stretching speed may lead to deviation of test results. The solution is to select the appropriate tensile speed according to the requirements of the test standard, and ensure the control accuracy and stability of the testing machine.

4. Data recording issues:

During the zipper strength testing process, it is crucial to accurately record the test data. Inaccurate or missing data records may lead to misinterpretation of test results or inability to perform effective data analysis. The solution is to use a suitable data acquisition system to ensure accurate recording of test data and timely data collation and analysis.

5. Results evaluation issues:

When evaluating results based on test data, difficulties may be encountered in interpreting the results or comparing them with standard requirements. The solution is to be familiar with the requirements of the test standards and analyze the results according to the evaluation methods provided by the standards. If in doubt, seek professional help or refer to relevant technical documents.

6. Instrument Calibration Issues:

The accuracy and stability of the testing instrument is critical to the results of the zipper strength test. Inaccurate test results may result if the test equipment is not regularly calibrated or is faulty. The solution is to regularly calibrate test instruments and ensure they function properly and measure accurately.

7. Sample damage problem:

In the zipper strength test, the sample may be damaged due to excessive force or other reasons. This may lead to invalid test results or inability to draw accurate assessment conclusions. The solution is to pay attention to control the test parameters during the test to avoid excessive tension or other unnecessary damage to the sample.

In a word, there are many problems that may be encountered in the zipper strength test, but through suitable solutions and strict operations, the influence of these problems on the test results can be minimized. When conducting a zipper strength test, it is recommended to read the test standards carefully to ensure the accuracy and reliability of the test process, and seek professional guidance and support when needed.

Previous: Flammability Testing of Textiles: Key Considerations

N e x t : Maintenance Tips for the Cone Calorimeter