NewsInformation Center

What are the factors affecting tear strength of fabric?

2023/11/06

The tear strength of fabric is an important property that determines its resistance to tearing or ripping when subjected to force. Several factors influence the tear strength of fabric, including fiber properties, yarn construction, fabric structure, finishing treatments, and testing conditions. Let's explore these factors in more detail:

1. Fiber Properties:

- Fiber Type: Different fibers have varying tear strength properties. For example, natural fibers like cotton and silk generally have lower tear strength compared to synthetic fibers such as nylon and polyester.

- Fiber Tenacity: Higher tenacity fibers tend to exhibit better tear strength because they have a greater ability to resist external forces.

- Fiber Fineness: Finer fibers generally have lower tear strength due to their reduced cross-sectional area, which makes them more prone to tearing.

2. Yarn Construction:

- Yarn Type: The choice of yarn, such as spun or filament, impacts tear strength. Filament yarns, which have continuous fibers, typically offer higher tear strength compared to spun yarns composed of shorter staple fibers.

- Yarn Twist: An increase in yarn twist can enhance tear strength by improving the binding between individual fibers. However, excessive twist may lead to decreased tear strength by causing fiber damage.

- Yarn Count: Higher yarn count (finer yarn) generally results in increased tear strength because of a higher fiber density.

3. Fabric Structure:

- Fabric Weave: The weave pattern affects tear strength. Plain weaves usually have lower tear strength compared to twill or satin weaves, as the interlacing points in plain weave are straightforward to tear.

- Fabric Weight: Heavier fabrics tend to have higher tear strength due to their denser construction and more substantial thread/fiber presence.

- Fabric Thickness: Thicker fabrics often exhibit better tear resistance as they offer more material to resist tearing forces.

4. Finishing Treatments:

- Resin Treatments: The application of resin finishes can improve the tear strength of fabric by enhancing fiber-to-fiber bonding and reducing fiber slippage.

- Coating/Lamination: The addition of coatings or lamination layers can enhance tear strength by providing an extra barrier and reinforcing the fabric structure.

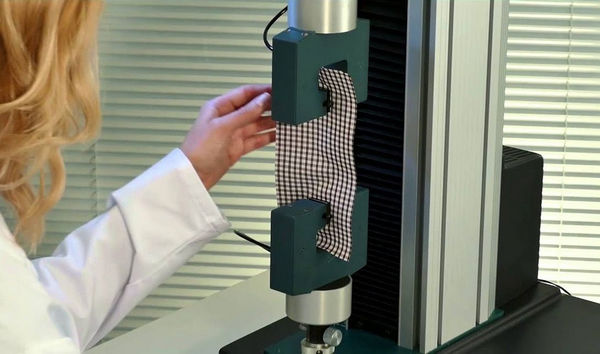

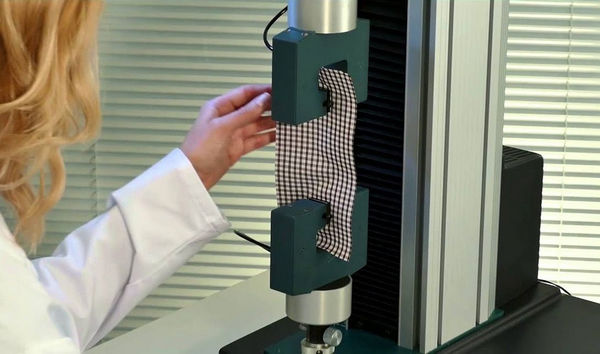

5. Testing Conditions:

- Specimen Dimensions: The size and shape of test specimens used for tear strength evaluation can impact the results. Standardized dimensions, such as the ASTM D2261 test method for Elmendorf tear strength, should be followed.

- Gripping Technique: The method used to grip the fabric during testing can affect the tear strength results. Improper gripping may lead to localized stress concentration and premature tearing.

- Testing Speed: The rate at which the fabric is subjected to tearing forces can influence the tear strength. Different test standards specify specific testing speeds to ensure consistency and comparability.

6. Environmental Factors:

- Moisture: The moisture content of the fabric can impact its tear strength. Some fibers, like cotton, may experience reduced tear strength when wet.

- Temperature: Extreme temperature conditions can affect the tear strength of certain fibers, especially thermoplastics.

7. Fabric Age and Wear:

- Degradation: Over time, fabric can undergo aging and degradation processes, leading to reduced tear strength. Factors such as exposure to sunlight, chemicals, and repeated use can contribute to fabric degradation.

- Mechanical Wear: Frequent stretching, abrasion, or bending of fabrics can weaken the fibers and reduce tear strength.

It's important to note that the tear strength of fabric is typically assessed using industry-standard test methods, such as the Elmendorf tear test (ASTM D2261) or the Tongue tear test (ASTM D5733). These tests provide reliable and standardized measurements, allowing for comparisons between fabrics and ensuring product quality and performance.

In summary, the tear strength of fabric is influenced by a combination of factors related to fiber properties, yarn construction, fabric structure, finishing treatments, testing conditions, and environmental factors. Understanding these factors can help in fabric selection, design considerations, and optimizing tear resistance for specific applications.

Previous: What are some other methods used to determine the flammability of textiles?

N e x t : What factors affect the price of xenon lamp climate aging test chamber?