NewsInformation Center

Fbric Tear Testing: All your questions answered

2023/11/15

Tear testing is a critical method used in the textile industry to evaluate the tear resistance of fabrics, textiles, and other materials. It involves subjecting a sample to a controlled force that causes a small tear to propagate through the material. Tear testing provides valuable information about the material's strength, durability, and resistance to tearing.

Here are the answers to some important questions related to tear testing:

1. Why is tear testing important?

Tear resistance is a crucial property of materials, especially those used in products subjected to tearing forces, such as clothing, upholstery, and industrial textiles. Tear testing helps manufacturers ensure that their products meet quality standards and can withstand the rigors of everyday use. It aids in material selection, product development, and quality control processes.

2. How is tear testing performed?

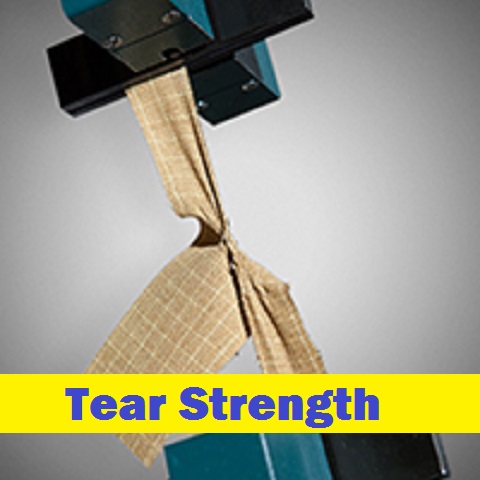

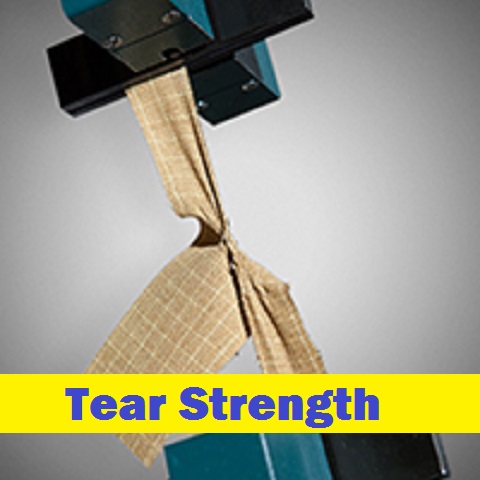

Tear testing is typically conducted using a machine called a tear tester or a tensile testing machine equipped with a tear testing attachment. The sample is usually cut into a specific shape, such as a rectangular strip or a trapezoid, with a precut notch in the center. The sample is clamped into the tear tester, and a controlled force is applied to initiate and propagate the tear. The force required to tear the material is measured and recorded.

3. What are the different tear test methods?

There are several tear test methods commonly used, including the Elmendorf tear test, the trouser tear test (often used for woven fabrics), the tongue tear test (often used for nonwoven materials), and the grab tear test (often used for knitted fabrics). These methods differ in terms of sample preparation, tear direction, and specific testing parameters. The choice of test method depends on the type of material and the specific application.

4. What tear test results can be obtained?

Tear test results typically include peak tear force (maximum force required to tear the material), tear propagation resistance (energy required to propagate the tear), and tear strength (force per unit thickness of the material). These results provide valuable information about the material's tear resistance and its ability to withstand tearing forces in different directions.

5. What factors can affect tear test results?

Several factors can impact tear test results, including the type of material, its thickness, the sample preparation method, the tear test method used, the testing speed, and the environmental conditions (temperature, humidity). Proper sample preparation, standardized testing procedures, and control of testing parameters are essential to obtain accurate and reproducible tear test results.

6. How are tear test results interpreted?

Tear test results are typically compared with specified standards or requirements to determine if the material meets the desired tear resistance criteria. It is important to consider the application-specific requirements and intended use of the material when interpreting tear test results. Comparisons can also be made between different materials or between variations in material composition or processing.

7. Can tear test results predict real-world performance?

While tear testing provides valuable information about material strength and tear resistance, it may not precisely reflect the material's performance in real-world conditions. Tear resistance can be influenced by various factors not accounted for in laboratory testing, such as seam strength, edge effects, surface treatments, aging, and exposure to environmental factors. Therefore, tear test results are best used as a comparative tool rather than an absolute indicator of real-world performance.

8. What are the limitations of tear testing?

Tear testing has its limitations and should be used in conjunction with other tests and evaluation methods to comprehensively assess material performance. Tear testing does not consider other failure modes, such as seam failure or puncture resistance. Additionally, tear test results can vary depending on the specific test method used, and not all tear test methods may be applicable to all types of materials.

9. Can tear testing be used for quality control?

Yes, tear testing is widely used for quality control purposes in the textile industry. By establishing tear resistance requirements and conducting regular tear testing on incoming materials or finished products, manufacturers can ensure consistent product quality and compliance with industry standards. Monitoring tear resistance helps identify deviations in material properties and enables corrective actions to maintain product integrity.

10. How can tear test results be improved?

To obtain accurate and reliable tear test results, it is important to follow standardized testing procedures, use calibrated equipment, and ensure proper sample preparation. Samples should be representative of the material being tested, and testing conditions should be controlled and consistent. Regular calibration and maintenance of tear testing equipment are essential to ensure accurate and repeatable results.

In conclusion, tear testing is a crucial tool in evaluating the tear resistance of materials in the textile industry. It helps manufacturers ensure product quality, optimize material selection, and meet industry standards. Proper testing procedures, accurate interpretation of test results, and consideration of real-world conditions are essential for effective tear testing.

Previous: Your Comprehensive Guide on How to Test Face Masks for Flame Resistance

N e x t : How long should a Martindale abrasion test be humidified?