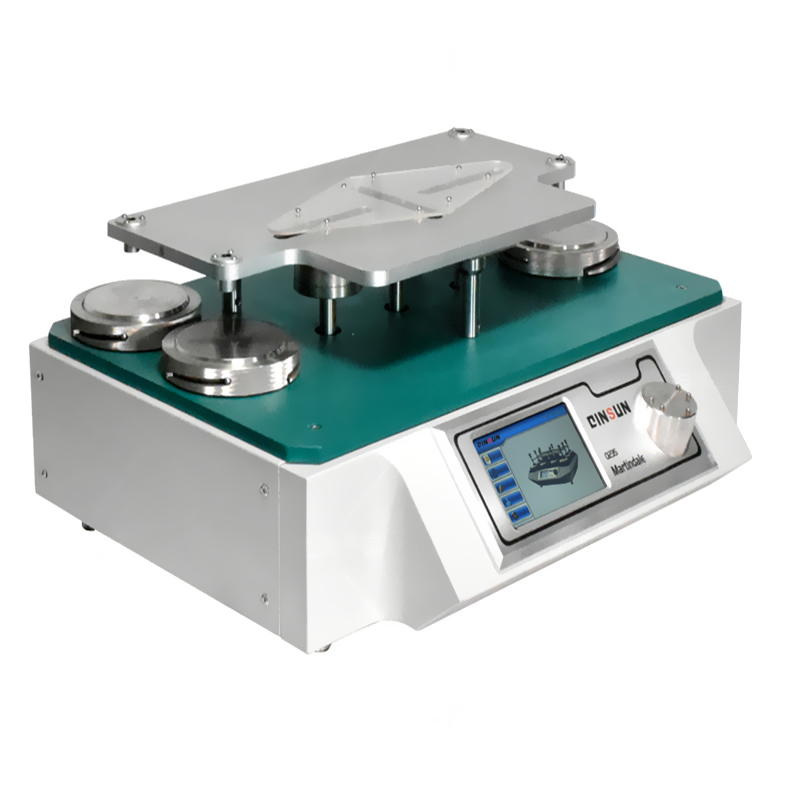

Martindale wear resistance and pilling tester operate precautions

2024/03/27

1. The friction cloth cannot be reused, and a new friction cloth needs to be replaced after each test is completed;

2. Wool felt can be reused. If there is wear or contamination on the surface, it needs to be replaced and can be used on both sides;

3. The insoles should be debuffed first before undergoing the Martindale abrasion test;

4. If there are abnormal phenomena such as abrasion, broken yarn, pilling or severe pilling, and severe wear on the surface of the sample after testing, it is judged as unqualified;

5. When making samples, special attention should be paid to cutting edges to avoid any hair changes, in order to avoid unnecessary quality loss and appearance changes.

Operation steps:

1. Preparation of samples

In a standard environment, place for a period of time in a flat and non stretched state according to different standard requirements. For example, 24 hours (GB/T 4802.2-1997), 16 hours (EN ISO 12947-4:1998)

2. Selection of samples

Cut a sample from different parts of the entire width material, and the sample should be representative. If it is a fancy fabric, the sample should include all the different textures and colors presented on the fabric surface;

3. Remove the load and load shaft from the testing machine;

4. Remove the top plate and testing fixture;

5. Sample device:

Loosen the fixing ring on the test fixture, take down the sample compression plate, and put the sample into the base of the test fixture. When the tested fabric is not more than 500g/m2, place a piece of polyester foam plastic between the sample and the metal stopper of the sample holder. When it is more than 500g/m2, or when it is a composite fabric, it is not necessary to pad foam plastic, and the samples on each sample holder should be subject to the same tension.

6. Device for wool felt and friction cloth:

Place the felt and abrasive on the grinding table, place the weight on the abrasive, then place the pressure ring, tighten the nut, so that the pressure ring fixes the abrasive on the grinding table.

7. Place the grinding head on the abrasive and apply pressure;

8. Place the test fixture with the sample facing downwards on the base fixture, adjust the circular groove of the test fixture to align with the load axis rod, so that the load axis rod is inserted into the circular groove of the test fixture;

9. According to the standard set number of times, start the switch, start the test, and automatically stop the machine after reaching the set number of times;

10. Remove the sample and compare it with the standard sample in the rating box.

Previous: bed blanket combustion tester technical features

N e x t : fabric bursting strength tester testing principle and steps