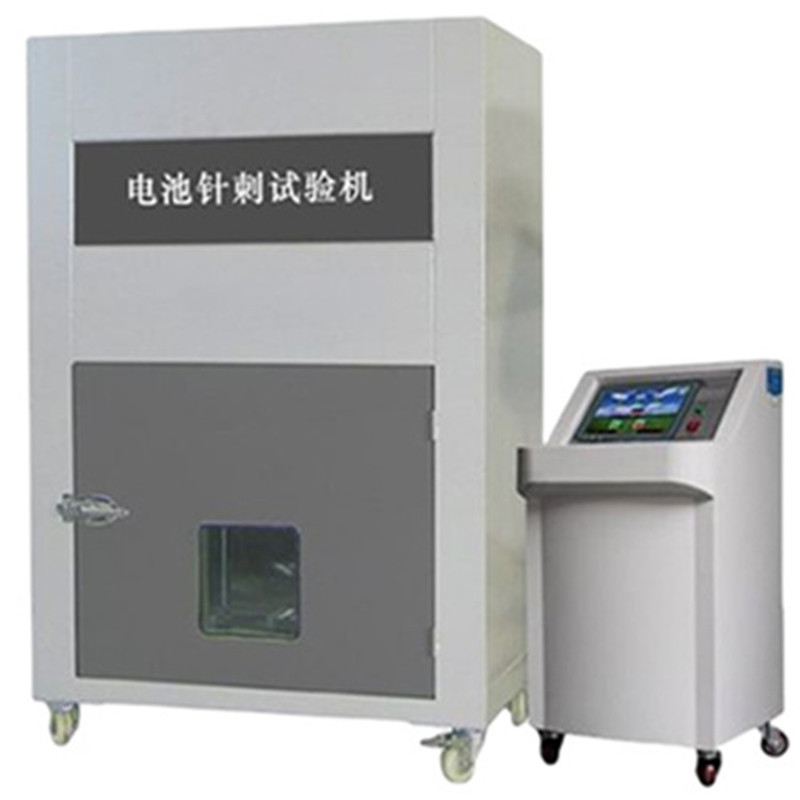

battery extrusion needle puncture testing machine parameters

2024/04/01

According to the standard:

QC/T 743-2006 "Standard for lithium-ion batteries for electric vehicles"

MT/T 1051-2007 "Lithium ion batteries for mining lamps - Needle puncture test"

UL2054:2008

GB/T 18332-2009

Main parameters:

1 ф 2mm - ф 8mm high-temperature resistant steel needle

2. Distance from the needle tip to the lower part: 250mm from the plane where the battery is placed

3. Clamping distance: 150MM

4. At a speed of 10-40mm/s, penetrate from the direction perpendicular to the battery plate (the steel needle stays in the battery)

5. Penetration force: 150-200KG

6. Power display: Pressure sensing LED display

7. Travel: 100mm

8. Driving method: cylinder driven

9. Power requirements: 1 ф, 220V, 50Hz

The battery extrusion needle puncture test machine is mainly used to simulate the reliability of the performance changes and safety performance of the battery after being punctured by sharp metal objects from the outside and damaged internally. It can complete needle puncture experiments on 5-50Ah power batteries and their small battery packs.

According to the standard:

QC/T 743-2006 "Standard for lithium-ion batteries for electric vehicles"

MT/T 1051-2007 "Lithium ion batteries for mining lamps - Needle puncture test"

UL2054:2008

GB/T 18332-2009

Main parameters:

1 ф 2mm - ф 8mm high-temperature resistant steel needle

2. Distance from the needle tip to the lower part: 250mm from the plane where the battery is placed

3. Clamping distance: 150MM

4. At a speed of 10-40mm/s, penetrate from the direction perpendicular to the battery plate (the steel needle stays in the battery)

5. Penetration force: 150-200KG

6. Power display: Pressure sensing LED display

7. Travel: 100mm

8. Driving method: cylinder driven

9. Power requirements: 1 ф, 220V, 50Hz

Previous: Battery combustion testing machine standards

N e x t : The vacuum pump has a slow pumping speed and a poor vacuum degree