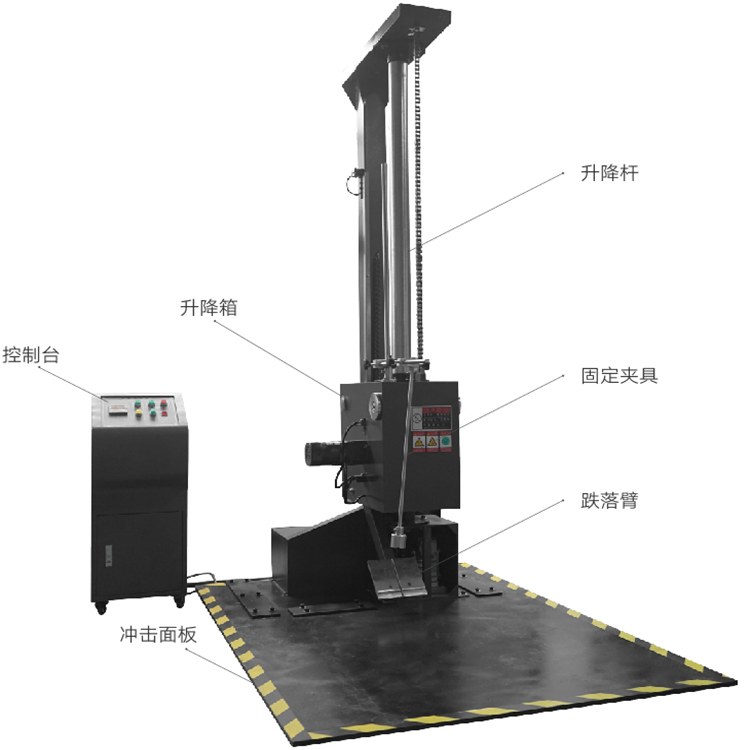

Packaging box drop tester parameters

2024/04/03

Compliant with standards:

ISO 248, JIS Z0202-87, GB/T 4857.5-92

Main parameters:

1. Drop height (mm): 300-1500;

2. Measurement weight (kg): not exceeding 100KG;

3. Sample size (mm): 800 × 800 × 800;

4. Impact panel size (mm): 1700 x 1200;

5. Arm size (mm): 160 x 180 x 8;

6. Drop error: < 1 °;

7. Drop height error (mm): ± 10;

8. Dimensions of the test bench (mm): approximately 1700 x 1200 x 2350, and dimensions of the control box (length, width, height): approximately 350 * 300 * 800mm.

Compliant with standards:

ISO 248, JIS Z0202-87, GB/T 4857.5-92

Main parameters:

1. Drop height (mm): 300-1500;

2. Measurement weight (kg): not exceeding 100KG;

3. Sample size (mm): 800 × 800 × 800;

4. Impact panel size (mm): 1700 x 1200;

5. Arm size (mm): 160 x 180 x 8;

6. Drop error: < 1 °;

7. Drop height error (mm): ± 10;

8. Dimensions of the test bench (mm): approximately 1700 x 1200 x 2350, and dimensions of the control box (length, width, height): approximately 350 * 300 * 800mm.

Previous: Fabric cooling performance tester parameters

N e x t : Packaging box clamping tester standards