NewsInformation Center

The Scratch Testing to characterizing coatings

2019/05/22

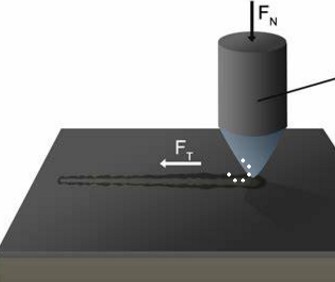

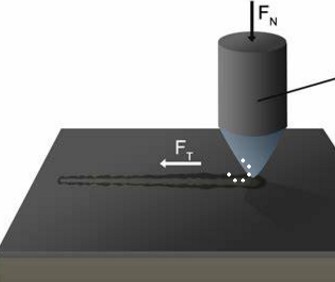

Scratch testing is invaluable to gain insight into materials such automotive paints, varnishes, as well as coatings. Scratch testing is a simple and rapid method of characterizing coatings, but results obtained are influenced by various factors such as coating thickness, substrate mechanical properties, interfacial bond strength, and test conditions such as scratch speed, load, and indenter tip radius.

Single asperity scratching allows the mechanisms behind abrasive or ductile damage to be understood without the complexity of multiple asperity contacts. A range of conical diamond tips (apical angle from 35° to 150°) are drawn across the surface under constant, stepwise or progressively increasing load.The morphology of the scratches is examined with a combination of microscopy and profilometry techniques.

Scratch hardness values are calculated to generate a scratch map that depicts the behaviour of the surface under a complete range of working conditions.Scratch testing can be automated to achieve Medium Throughput data generation.

Applications of Scratch Testing:

Commercial polymers

Paint and varnishes for the automotive industry

Multilayered systems

Application related performance

Application related performance;

Single asperity scratching allows the mechanisms behind abrasive or ductile damage to be understood without the complexity of multiple asperity contacts. A range of conical diamond tips (apical angle from 35° to 150°) are drawn across the surface under constant, stepwise or progressively increasing load.The morphology of the scratches is examined with a combination of microscopy and profilometry techniques.

Scratch hardness values are calculated to generate a scratch map that depicts the behaviour of the surface under a complete range of working conditions.Scratch testing can be automated to achieve Medium Throughput data generation.

Applications of Scratch Testing:

Commercial polymers

Paint and varnishes for the automotive industry

Multilayered systems

Application related performance

Application related performance;

Previous: The importance of Carpet wear test

N e x t : Significance of Material Antisepsis