What is the difference between conical and parallel twin-screw extruders?

2025/10/30

This article will delve into the structure, principle, performance characteristics, and application scenarios of conical and parallel twin-screw extruders, ultimately providing a clear selection reference through a detailed comparison table.

Parallel Twin-Screw Extruder

A parallel twin-screw extruder, as the name suggests, has two screws whose axes remain parallel throughout their entire length. The screw outer diameter is typically consistent or varies depending on the functional section (modular screw design).

Core Structure and Design Concept

The core feature of a parallel twin-screw extruder lies in its parallel screw axis layout. This allows for a classic "modular" design for both the barrel cavity and the screw itself. That is, the barrel sections and screw elements (conveyor blocks, kneading blocks, engagement discs, etc.) are standardized and modularized. Users can freely combine the screw and barrel structures like building blocks, based on specific process formulations and flows (such as feeding sequence, mixing intensity, and devolatilization location). This design gives parallel twin-screw extruders unparalleled flexibility.

Their length-to-diameter ratio (L/D, the ratio of effective screw length to diameter) is typically large, commonly ranging from 36:1 to 60:1. or even higher. A large aspect ratio means longer material residence time within the barrel, allowing for more process sections (such as multiple feed ports and multiple vacuum devolatilization ports), providing ample space and time for complex physicochemical processes.

Operating Characteristics and Advantages

Superior Mixing Capacity: Parallel twin-screw extruders, especially the tightly meshed type, exhibit very high surface renewal rates and shear efficiency. By adjusting the number and angle of the kneading blocks, the shear strength and dispersion mixing effect on the material can be precisely controlled, making it ideal for preparing highly filled masterbatches, nanocomposites, sensitive color masterbatches, and other products requiring extremely high mixing uniformity.

Powerful Deviation Capacity: Due to the ability to set up multiple vacuum devolatilization ports and the screw's ability to effectively renew the material surface, parallel twin-screw extruders perform exceptionally well in removing volatiles (such as solvents, moisture, and reaction byproducts). This is crucial for polymer devolatilization, concentration, and certain chemical reactions requiring the removal of small molecules.

Superior Self-Cleaning Capability: The co-rotating parallel twin-screw extruder, in the meshing zone, allows the screw edges of one screw to sweep across the grooves of the other at a certain speed, effectively scraping away adhering material and preventing degradation and material buildup. This is crucial for processing heat-sensitive materials (such as PVC and biopolymers) and in R&D environments requiring frequent material changes.

High-Pressure Extrusion Capability: While pressure build-up primarily relies on die resistance and end-feed components, the parallel twin-screw extruder can establish stable high pressure at the die head, ensuring the density and stability of extruded products (such as granules and sheets).

Typical Application Scenarios

Parallel twin-screw extruders are the absolute mainstay of modern polymer material R&D and production.

Polymer Blending and Alloying: Such as PC/ABS alloys, TPE, etc.

Filling and Reinforcement Modification: Preparation of high-proportion calcium carbonate and talc filler masterbatches, or glass fiber and carbon fiber reinforced composites.

Reactive Extrusion: Chemical reactions such as polymerization, grafting, and functionalization occur within the screw.

Food and Pharmaceuticals: Used for breakfast cereals, textured proteins, and pharmaceutical granulation.

Laboratory Research and Development: Due to its flexibility, it is the preferred equipment for new product development and formula screening.

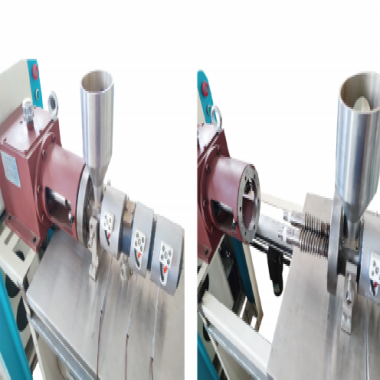

Conical Twin-Screw Extruder

The two screw axes of a conical twin-screw extruder are at a certain angle. The screw diameter gradually decreases from the feeding section to the metering section, and the screw channel depth also becomes shallower, resulting in an overall conical shape.

Core Structure and Design Concept

The "conical" shape is its most prominent feature. This structural design is not aimed at pursuing ultimate mixing flexibility, but rather at smooth, stable, and high-pressure conveying and melting. In the feeding section, the large screw diameter and deep screw channel provide powerful feeding capacity, effectively capturing and conveying loose or non-flowing materials (such as PVC powder). As the material is conveyed forward, the screw channel volume gradually decreases, and the material is gradually compressed and compacted, preparing for melting.

Conical twin-screw extruders typically rotate in opposite directions (outward or inward). The counter-rotating characteristic forces material forward between the two screws, similar to the effect of a gear pump, resulting in high conveying efficiency and minimal backflow and mixing. This leads to a narrower residence time distribution of material within the barrel, which is particularly advantageous for processing heat-sensitive materials.

Operating Characteristics and Advantages

Mild Shearing and Low Energy Consumption: The counter-rotating conical twin-screw extruder exerts relatively mild shearing action on the material, generating less frictional heat. Simultaneously, due to its forced conveying characteristics, energy is primarily used for conveying and compressing the material, rather than for intense shearing; therefore, energy consumption per unit output is typically lower than that of a parallel twin-screw extruder.

Excellent Pressure Build-up and Stability: The conical structure itself acts as a natural pressure booster. Material is "pushed" from the larger diameter end to the smaller diameter end, naturally creating compression. Combined with the forced conveying characteristic of counter-rotating rotation, this allows for the establishment of very stable and powerful pressure at the die head. This is crucial for the production of profiles requiring stable extrusion and precise shapes (such as doors, windows, and pipes), effectively ensuring the dimensional accuracy and density of the finished products.

Inherent Feeding Advantages: The large space at the feed port makes it ideal for directly processing powdered formulations, avoiding the risk of bridging at the feed port.

High Torque Transmission Capacity: The large screw root diameter in both the feeding and compression sections allows it to withstand and transmit extremely high torque, making it suitable for processing high-viscosity materials.

Typical Application Scenarios

Conical twin-screw extruders are king in specific fields, especially in PVC processing where they are almost irreplaceable.

PVC Product Processing: The standard configuration for producing rigid and flexible PVC pipes, profiles, and sheets. Its gentle shear and short residence time effectively prevent thermal degradation of PVC.

Other Heat-Sensitive Materials: It can also be used to process CPVC, wood-plastic composites, etc.

Profile Extrusion: For any product requiring stable, high-pressure, and continuous extrusion shaping, conical twin-screw extruders provide superior performance.

In-Depth Comparison of Core Differences and Selection Logic

The choice between conical and parallel extruders is not a matter of superiority or inferiority, but rather a debate about applicability. The fundamental logic lies in the core contradictions of process requirements. If your core process involves mixing, reaction, or devolatilization, you need a long, flexibly configurable "chemical reactor." Then, a parallel twin-screw extruder is the perfect choice. Its modular design and large aspect ratio provide a stage for complex physicochemical processes.

If your core process involves stable, high-pressure extrusion molding, especially for processing heat-sensitive powder formulations, you need a robust, reliable, and efficient "booster pump." In this case, a conical twin-screw extruder, with its inherent structural advantages, offers unparalleled stability and output quality.

There is no one-size-fits-all answer when choosing between conical and parallel twin-screw extruders. The parallel twin-screw, with its unparalleled flexibility and powerful mixing and reaction capabilities, dominates the vast field of new material development and high-value-added modification, serving as the innovation engine of modern polymer materials engineering. Conical twin-screw extruders, with their robust structure, stable extrusion performance, and inherent advantages for heat-sensitive materials (especially PVC), play an unshakeable cornerstone role in continuous, high-volume production, such as large-scale profile extrusion.

Decision-makers should start with the "core process requirements" of their products: is it to pursue ultimate mixing and chemical reaction, or ultimate extrusion stability and molding precision? Answering this question clearly will clarify the direction to choose. In today's trend of technological convergence, hybrid equipment combining conical and parallel sections has emerged, demonstrating that both technological approaches have their merits and jointly drive the entire extrusion industry forward.

Previous: What is a Mullen test?

N e x t : How to test toxic gases from building materials?