NewsInformation Center

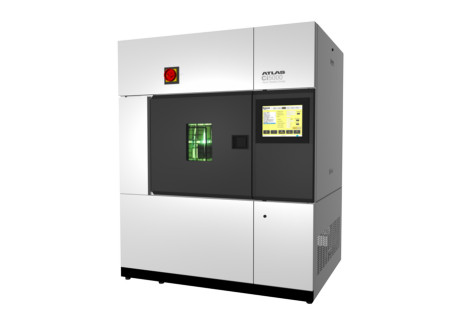

Aging Test Chamber: Two Tests and Requirements for Ventilation Aging

2022/05/13

The principle of the ventilation aging test box is to test the performance of the sample after the sample is air-aged under the condition of high temperature and atmospheric pressure, and compare the performance with the unaged sample. The degree of aging is judged by physical properties relevant to the use. If these properties cannot be accurately determined, it is recommended that tensile strength, tensile stress, elongation at break and hardness be determined.

1. Hot air accelerated aging test

During the experiment, the concentration of oxygen was very low, and even in the case of rapid oxidation, the oxygen could not diffuse into the rubber interior sufficiently to maintain continuous oxidation. Thus, when specimens of the thickness specified in the standard test method are suitable for use in this test method, this aging test method may produce erroneous results for rubber with poor aging properties.

2. High temperature resistance test

In this test method, a sample is subjected to the same temperature and time period as used, tested for proper performance, and compared to an unaged sample. The rubber samples tested in the ventilation aging test chamber should meet the following requirements:

1. The sample has a forced air circulator, the air flow rate is 0.5m/s~1.5m/s, and the smallest surface of the sample surface is facing the airflow to avoid disturbing the airflow speed;

2. The size of the ventilation aging test box should be such that 10% of the total sample volume does not exceed 10% of the effective volume of the box, and the suspended sample should be at least 10cm away from the box wall;

3. There must be a temperature control device to ensure that the temperature of the sample remains within the allowable range of the specified test temperature;

4. The heating chamber is equipped with a thermometer to record the actual heating temperature; its structure cannot use steel or copper alloy;

5. The number of air changes per hour is 3 to 10 times;

6. Before the sample enters the ventilation aging test chamber, the air must be heated to the allowable range of the specified test temperature.

Do you have a deeper understanding of the aging test box after reading these? Interested customers are welcome to inquire or leave a message to us to get the latest quotation of the aging test box!

Previous: 5 scratch test methods for automotive interior and exterior trims

N e x t : Constant temperature and humidity test chamber requirements for water