NewsInformation Center

What are the main parts of the mask particle filtration tester?

2022/09/21

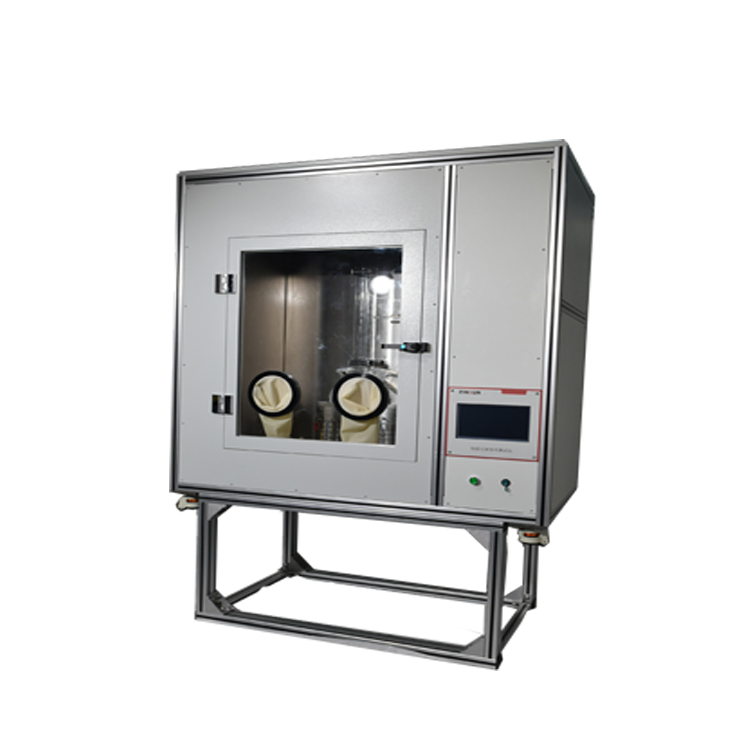

The mask particle filtration tester is composed of biological aerosol generation system, aerosol chamber, aerosol transmission device, negative pressure cabinet, sampler, and the whole tester is controlled by the control system for unified control. It is suitable for medical equipment inspection center, safety protection inspection center, labor protection inspection center, drug inspection center, disease prevention and control center, textile testing center, hospitals, mask manufacturers, etc. to test the bacterial filtration of masks.

Mask particle filtration tester instrument key components are as follows.

1. Salt / oil mist aerosol generation system: can produce salt / oil aerosol that meets the standard particle size distribution requirements;

2. Salt spray aerosol heating system: to produce salt particles;

3. Static distance system: used to neutralize the static electricity in the salt mist aerosol;

4. Filter media clamps: for clamping filter media or masks;

5. Differential pressure sensor: used to measure the differential pressure upstream and downstream of the filter material;

6. Mixing chamber: Mixing heated gas and salt spray aerosol to produce salt particles as required;

7. Solute switching system: convenient to switch aerosols;

8. Particle counter: used to measure the number of particles upstream and downstream of the filter material;

9. Flow controller: control and adjust the measuring air volume;

Mask particle filtration tester routine maintenance methods are as follows.

1. can clean the power sampling head or sampling tube, instrument and equipment mouth and other temporary storage of particles, can exclude the problem of inaccurate measurement due to temporary storage of particles.

2. Test the power supply and wiring, check the wiring or terminals for loose aging, short-circuit phenomenon, can eliminate hidden problems, reduce the failure rate, extend the service life of the instrument and equipment, spend a little money, save a lot of money.

3. Check the air pipe for blockage or leakage.

4. Strengthen the training of employees and improve their knowledge of the use and management of instruments and equipment.

Previous: How to use the moisture resistance microbial penetration tester correctly?

N e x t : Analysis of the current quality of Chinese masks