NewsInformation Center

Technical requirements for combustion chamber air tightness testing equipment

2022/11/09

The air tightness testing equipment is suitable for the tightness of the car controller, the waterproof test of the car lamp, the waterproof test of the charging gun, the air tightness performance is stable, the cost performance is high, the air tightness testing service can be provided, the cost-effective air tightness testing equipment, multi-channel air tightness detection.

1. Air tightness test

Test purpose: Whether the mixture in the combustion chamber leaks into the water jacket.

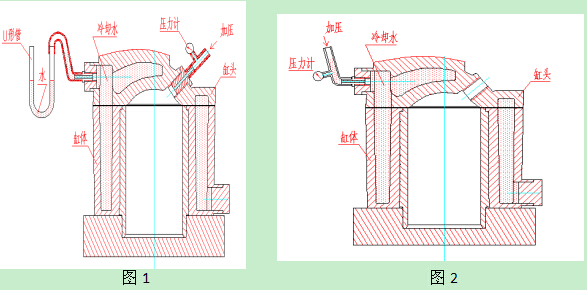

Test method: add nitrogen to the combustion chamber, the pressure requirement reaches 60bar, the schematic diagram is shown in Figure 1:

Working principle diagram

2. Water tightness test, the schematic diagram is shown in Figure 2

Test purpose: To confirm whether the cooling water in the water jacket enters the combustion chamber.

Test method: Add air to the water jacket.

⑴. Blow out the joint surface of the cylinder head with an air gun, and then spray the developer.

⑵.Pressurize into the water jacket, the pressure is 0.4MPa, and the pressure is maintained for 5min.

⑶. Confirm that the pressure does not drop within 5 minutes.

⑷. Drain the cooling water in the cylinder liner and check whether the developer is discolored

3. Deformation measurement of the joint surface of the cylinder head

Test purpose: To confirm whether the cooling water in the water jacket enters the combustion chamber.

Test method: Add oil or nitrogen to the combustion chamber, the pressure is required to reach 80bar, measure the deformation of the joint surface of the cylinder head, and keep the pressure for 5 minutes. The schematic diagram is shown in Figure 1.

illustrate:

1. The equipment is equipped with a test bench, and the engine can be installed on the test bench.

2. Test method: mainly consider the nitrogen detection method, but the third item should consider the use of oil pressurization.

3. The volume of the test piece: 100cc~800cc.

4. Control method: computer control, can automatically set pressure and pressure holding time.

5. Due to the high pressure, safety protection devices are required.

Previous: Introduction of ZwickiLine Materials testing machines

N e x t : Comparison of Vietnam's yarn exports in September/October 2022