NewsInformation Center

What factors can affect the results of a rubbing fastness test?

2023/06/09

The Rubbing fastness test is a test method used to evaluate the color durability of textiles. The test results can be used to compare the color durability of different textiles, or to determine the applicable use of specific textiles. However, the results of the rubbing fastness test may be affected by many factors, so these factors need to be paid attention to when conducting the test to ensure that the test results are comparable and reliable.

This article will discuss in depth what factors will affect the results of crock fastness testing, including testing conditions, testing equipment, testing methods, sample preparation, and testing environment.

1. Test conditions

Test conditions are one of the important factors affecting the results of rubbing fastness tests. The test conditions include test temperature, humidity, pressure, the shape and size of the friction head, the magnitude of the friction force, etc. Changes in these conditions may affect the test results, so the test conditions need to be strictly controlled when performing the test to ensure that the test results are comparable and reliable.

1.1. Test temperature and humidity

Testing temperature and humidity can affect the physical and chemical properties of textiles, thereby affecting test results. For example, when tested in a high-humidity environment, textiles may expand or contract, causing inaccurate test results. Therefore, when testing the rubbing fastness, the test temperature and humidity should be strictly controlled according to the standard requirements to ensure that the test results are comparable and reliable.

1.2. Test pressure

The test pressure refers to the force exerted by the testing machine on the textile. The size of the test pressure will affect the deformation and deformation of the textile surface, and then affect the accuracy of the test results. Generally, the test pressure should be adjusted according to the standard requirements to ensure that the test results are comparable and reliable.

1.3. The shape and size of the friction head

The shape and size of the friction head can affect the accuracy of the test results. For example, when testing with a smaller rubbing head, the color change on the surface of the textile may be more noticeable, so the test result may be lower. Therefore, when performing the rubbing fastness test, the appropriate rubbing head should be selected according to the standard requirements to ensure that the test results are comparable and reliable.

1.4. The magnitude of friction

The amount of friction will affect the degree of wear on the textile surface, thereby affecting the test results. For example, when testing with higher friction forces, the test results may be lower. Therefore, when performing the rubbing fastness test, the appropriate friction force should be selected according to the standard requirements to ensure that the test results are comparable and reliable.

2. Test equipment

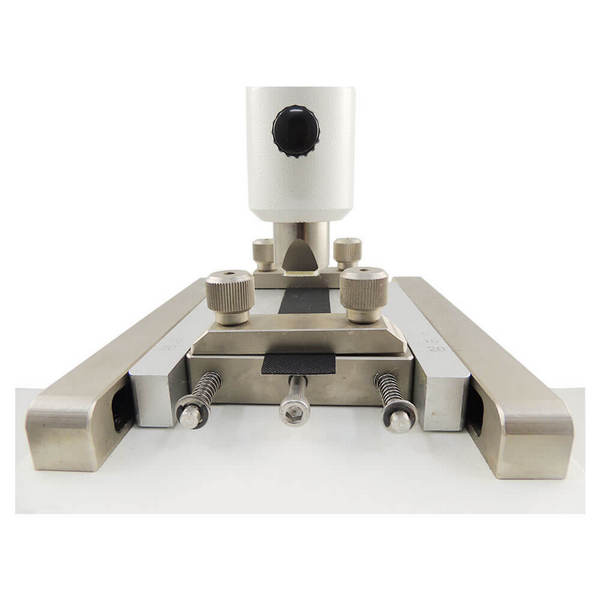

Testing equipment is another important factor affecting the results of crock fastness testing. Different test equipment is different in terms of test principles, test methods, and interpretation of test results. Therefore, when selecting test equipment, the test conditions should be determined according to specific applications and standards.

2.1. Martindale Abrasion and Pilling Tester

The Martindale Abrasion and Pilling Tester is a commonly used testing device to test the abrasion and pilling of the fabric surface. However, when using this tester, due to the influence of factors such as the thickness and elasticity of the sample, the test results may be biased.

2.2. Wyzenbeek Tester

The Wyzenbeek tester is a commonly used testing device to test the wear and durability of fabric surfaces. The tester simulates the way humans use fabrics for testing, so the test results are more realistic and reliable. However, when using this tester, attention needs to be paid to the control of test conditions and the quality of sample preparation to ensure that the test results are comparable and reliable.

3. Other test equipment

Apart from Martindale Abrasion and Pilling Tester and Wyzenbeek Tester, there are many other testing equipments that can be used for crock fastness testing, such as Taber Abrasion Tester, Crocker Abrasion Tester, etc. When selecting test equipment, it is necessary to determine the type and parameters of the test equipment according to specific requirements and standard requirements to ensure that the test results are comparable and reliable.

3. Test method

The test method is another important factor affecting the results of the rubbing fastness test. Different test methods are different in terms of test principles, test conditions, and interpretation of test results, so it is necessary to select an appropriate test method for testing.

3.1. Dry friction method

The dry rubbing method refers to the method of rubbing fastness testing under dry conditions. This method is suitable for testing dry-cleaned or dried fabrics. When using this test method, it is necessary to pay attention to factors such as the test pressure, the shape and size of the friction head, and the magnitude of the friction force to ensure that the test results are comparable and reliable.

3.2. Wet rubbing method

Wet rubbing method refers to the method of rubbing fastness test under wet conditions. This method is suitable for testing washed or wet fabrics. When using this test method, it is necessary to pay attention to factors such as test temperature, humidity, test pressure, shape and size of the friction head, friction force, etc., to ensure that the test results are comparable and reliable.

4. Sample preparation

Sample preparation is another important factor affecting the results of crockfastness testing. The quality and state of sample preparation may affect the accuracy and reliability of test results.

4.1. Selection of samples

When performing a rubbing fastness test, it is necessary to select a suitable sample for testing. Sample selection may affect the reliability and accuracy of test results. Therefore, when selecting samples, it is necessary to pay attention to the fiber material, dyeing method, yarn density and other factors of the sample to ensure that the test results are comparable and reliable.

4.2. Sample Preparation

When performing crock fastness testing, sample preparation and handling are required. Sample preparation may affect the accuracy and reliability of test results. Therefore, when preparing samples, it is necessary to pay attention to the size, shape, thickness, stitching method and other factors of the samples to ensure that the test results are comparable and reliable.

5. Test environment

The test environment is another important factor that affects the results of the rubbing fastness test. The testing environment may affect the reliability and accuracy of test results.

5.1. Laboratory environment

When performing Rubbing fastness test, testing is required in a laboratory. Factors such as temperature, humidity, and noise in the laboratory environment may affect the accuracy and reliability of test results. Therefore, when testing, it is necessary to test in a laboratory environment that meets the requirements of the standard to ensure that the test results are comparable and reliable.

Previous: Exploring the Different Types of Tearing Test Methods

N e x t : International news: Brazil's cotton price decline intensified in April