Search keywords:

product name, product type, model number,

test method, manufacturer, technique, application

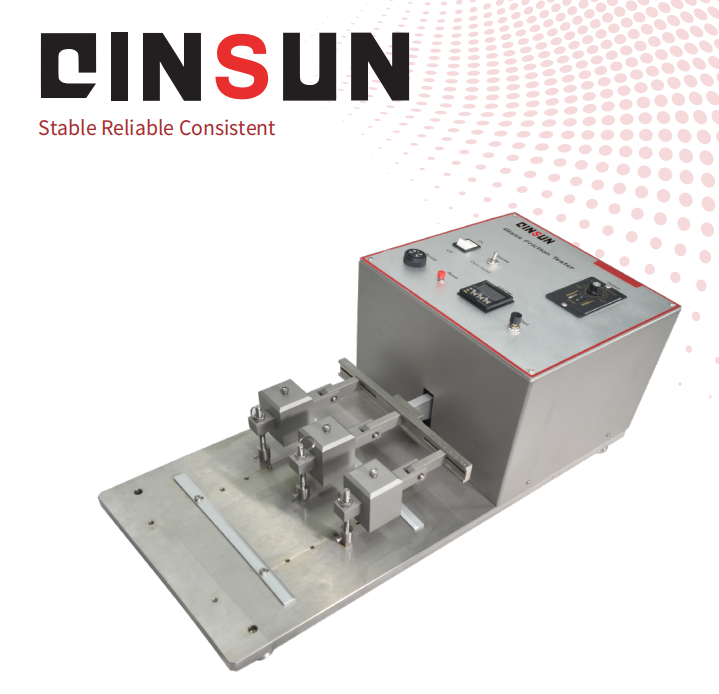

Glass Scratch/Abrasion Tester

BACKStandards:

Applications:

Product Information:

The Glass Scratch/Abrasion Tester is used to test the scratch and abrasion resistance of glass. This instrument uses a counter to set the number of rubbing cycles and a speed controller to adjust the operating speed of the rubbing head to meet the customer's actual testing needs. During the test, a 10mm*10mm rubbing head equipped with steel wool is used. Adjustable weights adjust the pressure load of the rubbing head to rub the glass. After the test, the sample is removed and its scratch and abrasion resistance is evaluated.

Applications

Automotive Glass: Assesses windshield durability against environmental wear.

Consumer Electronics: Tests smartphone screens, tablet covers, and display panels.

Architectural Glass: Validates window and facade materials for long-term performance.

Medical Devices: Ensures compliance with biocompatibility standards (e.g., ISO 10993-7).

Standards

ISO 10993-7: Biological Evaluation of Medical Devices – Ethylene Oxide Sterilization Residuals

USP (United States Pharmacopeia): Container Performance Testing

Ph. Eur. (European Pharmacopoeia): Glass Containers for Pharmaceutical Use

JP (Japanese Pharmacopoeia): Glass Container Testing Standards

GB/T 16886.7: Biological Evaluation of Medical Devices – Ethylene Oxide Sterilization Validation

Features

Three Independent Workstations: Enables parallel testing of diverse glass types.

Adjustable Friction Head: 10mm × 10mm steel wool attachment with load regulation (0–10N).

Speed Governor: Controls reciprocating motion (50 ±5 mm stroke) up to 120 RPM.

Safety Interlocks: Prevents accidental start-up and overload damage.

Easy Sample Handling: Quick-release clamps for rapid sample exchange.

Digital Display: Monitors test parameters (load, speed, cycles) in real time.

Technical Parameters

| Parameter | Specification |

|---|---|

| Control Mode | Automatic (PLC) |

| Maximum Load | 10 N (Adjustable) |

| Speed Range | 0–120 RPM (Reciprocating) |

| Stroke Length | 50 ±5 mm |

| Workstations | 3 (Independent) |

| Friction Head Size | 10 mm × 10 mm (Steel Wool Attachment) |

| Power Supply | AC 220V ±10%, 50Hz |

| Dimensions (L×W×H) | 800 mm × 400 mm × 500 mm |

| Net Weight | 85 kg |

| Display | LED Touchscreen (Load/Speed/Cycle Control) |

Test Procedures

Place the cut sample on the sample clamping platform and clamp it securely.

Fix the weights, ensuring full contact between the friction head and the sample, and tighten the device.

Turn on the machine and select the desired test mode (specified number of times or continuous operation). Then set the desired number of friction cycles and the desired operating speed.

Turn on the speed controller switch and press the start button; the equipment will begin operation.

After the test, record the surface friction of the sample and assign a relevant rating.

Maintenance Method

Product Maintenance Method (Based on Equipment Structure and Usage Information)

Regularly clean the friction head and sample clamping area to prevent residual abrasive particles from affecting test results.

Inspect the wear of the steel wool friction head; replace it promptly if it affects friction performance.

Regularly inspect the counterweight device and clamps to ensure stable loading and reliable fixation.

Keep the equipment's working environment clean and dry to prevent dust and moisture from affecting the control system.

Regularly check the touchscreen display and control parameters to ensure accurate and reliable test data.

Accessories

Accessories (Based on Product Structure and Test Configuration)

10 mm × 10 mm Friction Head (Steel Wool Mounting Structure)

Adjustable Counterweight Assembly (For Applying 0–10 N Pressure)

Sample Quick Clamping Device

Three-Station Independent Testing Platform

Control and Display System (PLC Control + LED Touchscreen)

FAQs

1. What is the main function of the Glass Scratch/Abrasion Tester?

The Glass Scratch/Abrasion Tester is used to evaluate the scratch resistance and abrasion resistance of glass materials. During testing, a 10 mm × 10 mm rubbing head equipped with steel wool rubs against the glass surface under a controlled load and speed. By setting the number of rubbing cycles and operating speed, the tester simulates repeated friction on glass surfaces. After testing, the glass sample is removed and its surface condition is examined to assess scratch and abrasion performance.

2. How does the tester control test conditions such as load, speed, and cycles?

The tester uses a combination of an automatic PLC control system, adjustable weights, a speed governor, and a cycle counter to control test conditions precisely. The pressure applied by the friction head can be adjusted from 0 to 10 N using weights, while the reciprocating speed can be set within a range of 0–120 RPM. The stroke length is maintained at 50 ±5 mm. Operators can select either a specified number of friction cycles or continuous operation. Real-time values for load, speed, and cycle count are displayed on the LED touchscreen.

3. What applications is this tester suitable for?

The Glass Scratch/Abrasion Tester is suitable for a wide range of applications, including durability evaluation of automotive glass such as windshields, scratch resistance testing of consumer electronics displays, long-term performance validation of architectural glass, and surface performance assessment of glass used in medical devices. It supports testing needs in product development, quality control, and material performance evaluation across multiple industries.

4. What design features improve testing efficiency and safety?

The tester is equipped with three independent workstations, allowing parallel testing of different glass samples to improve efficiency. Quick-release clamps enable fast and secure sample mounting and removal. Safety interlocks are integrated to prevent accidental start-up and overload damage. The adjustable friction head with a standard 10 mm × 10 mm steel wool attachment ensures consistent contact with the sample surface. In addition, the digital display provides real-time monitoring of test parameters, helping operators maintain stable and repeatable test conditions.