Search keywords:

product name, product type, model number,

test method, manufacturer, technique, application

Hydrogen Sulfide Corrosion Test Chamber

BACKStandards:

(1) GB/T 978.9-88 – Corrosion Test of Metal and Non-Metal Coatings Under Condensing Sulfur Dioxide. (2) ISO 6988 – Corrosion Tests in Artificial Atmospheres – Sulfur Dioxide Tests. (3) QB/T 3831 – Color Change Resistance Test for Metal Plating and Chemical Treatment Layers. (4) GB 2423.20-81 – Hydrogen Sulfide Test for Electrical Products. (5) Additional international and national standards for gas corrosion, environmental simulation, and accelerated aging tests.

Applications:

(1) Testing corrosion resistance of metal and non-metal coatings.

(2) Evaluating color change resistance of metal plating and chemical treatment layers.

(3) Assessing durability of electrical products and components exposed to H₂S gas.

(4) Material quality control in automotive, aerospace, and industrial manufacturing.

(5) Research and development of protective coatings and corrosion-resistant materials.

(6) Certification and compliance testing for domestic and international standards.

(7) Laboratory evaluation of alloys, steels, copper, zinc, nickel, and painted or plated surfaces.

Product Information:

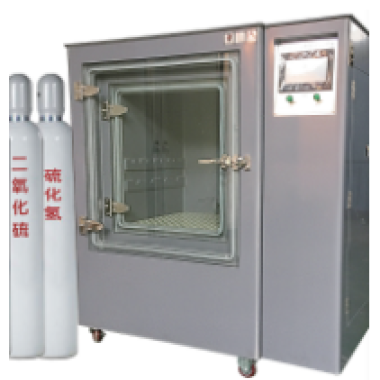

The Hydrogen Sulfide Corrosion Test Chamber is a precision environmental testing instrument designed to evaluate the corrosion resistance of metals, coatings, and chemical-treated surfaces under controlled hydrogen sulfide (H₂S) gas conditions. It provides accurate control of temperature, humidity, and H₂S concentration, allowing simulation of corrosive environments to assess material durability, color change, and coating performance.

Application

(1) Testing corrosion resistance of metal and non-metal coatings.

(2) Evaluating color change resistance of metal plating and chemical treatment layers.

(3) Assessing durability of electrical products and components exposed to H₂S gas.

(4) Material quality control in automotive, aerospace, and industrial manufacturing.

(5) Research and development of protective coatings and corrosion-resistant materials.

(6) Certification and compliance testing for domestic and international standards.

(7) Laboratory evaluation of alloys, steels, copper, zinc, nickel, and painted or plated surfaces.

Standards

(1) GB/T 978.9-88 – Corrosion Test of Metal and Non-Metal Coatings Under Condensing Sulfur Dioxide.

(2) ISO 6988 – Corrosion Tests in Artificial Atmospheres – Sulfur Dioxide Tests.

(3) QB/T 3831 – Color Change Resistance Test for Metal Plating and Chemical Treatment Layers.

(4) GB 2423.20-81 – Hydrogen Sulfide Test for Electrical Products.

(5) Additional international and national standards for gas corrosion, environmental simulation, and accelerated aging tests.

Features

(1) High-precision PID microcomputer controller with 0.1°C resolution.

(2) Stable temperature control: ±0.5°C or ±2°C depending on model.

(3) Bottled gas supply system with precise H₂S concentration regulation (0.1–1% v/v).

(4) Humidity control: 93–98% RH with ±2% deviation.

(5) Titanium alloy nickel-chromium heating system with PID+SRR synchronization.

(6) Safety protections including leak detection, short-circuit protection, and over-temperature protection.

(7) Equipped with 6 V-shaped corrosion-resistant racks and 12 O-shaped test rods.

(8) Robust rotary table system allowing simultaneous testing of multiple samples.

Technical Parameters

| Model | Inner Chamber Size (W×D×H) | Outer Dimensions (L×W×H) | Power Consumption (kW) | Temperature Range | Humidity Range | Gas Concentration |

|---|---|---|---|---|---|---|

| H2S-150 | 450×600×450 mm | 680×1000×1050 mm | 1.1 | 25–40°C | 93–98% RH | 25±5 ppm |

| H2S-250 | 600×900×500 mm | 850×1420×1120 mm | 1.2 | 25–40°C | 93–98% RH | 25±5 ppm |

| H2S-750 | 750×1100×500 mm | 1000×1650×1320 mm | 2.1 | 25–40°C | 93–98% RH | 25±5 ppm |

| H2S-010 | 850×1300×550 mm | 1150×1900×1370 mm | 2.2 | 25–40°C | 93–98% RH | 25±5 ppm |

Accessories

(1) Gas regulators and safety valves.

(2) Sample holders: 6 V-shaped racks, 12 O-shaped test rods.

(3) Power cable and grounding cable.

(4) User manual and product qualification certificate.

(5) Optional data logging and timer extension modules.

Test Procedures

(1) Place test samples onto V-shaped racks or O-shaped rods.

(2) Insert the sample holders into the rotary table and secure the chamber.

(3) Set target temperature, humidity, and H₂S concentration on the controller.

(4) Activate fan rotation for uniform gas distribution across all samples.

(5) Run the test for the designated duration according to the selected standard.

(6) Record weight changes, color change, or corrosion effects after exposure.

(7) Repeat testing for multiple cycles or comparative studies as needed.

Maintenance Information

(1) Regularly inspect gas supply system and valves for leaks.

(2) Calibrate temperature and humidity sensors periodically.

(3) Clean chamber interior and sample holders to prevent residue build-up.

(4) Verify fan operation and rotary mechanism to ensure uniform gas distribution.

(5) Store the instrument in a dry environment and avoid direct sunlight exposure.

(6) Check electrical components, PID controller, and safety interlocks before each use.

FAQs

1. What is the primary function of the Hydrogen Sulfide Corrosion Test Chamber?

The Hydrogen Sulfide Corrosion Test Chamber is used to evaluate the corrosion resistance of metals, coatings, and chemically treated surfaces under controlled hydrogen sulfide (H₂S) gas environments. By accurately controlling temperature, humidity, and gas concentration, the chamber simulates corrosive atmospheres that materials may encounter in real service conditions. The test results are used to assess corrosion behavior, coating durability, and color change, providing reliable data for material selection, quality control, and product certification.

2. Which industries and materials are suitable for testing with this chamber?

This test chamber is suitable for a wide range of industries, including automotive, aerospace, electrical manufacturing, and general industrial production. It is commonly used to test alloys, steels, copper, zinc, nickel, as well as painted, plated, or chemically treated surfaces. Electrical components exposed to H₂S gas can also be evaluated for durability and corrosion resistance. In addition, it supports research and development of protective coatings and corrosion-resistant materials, as well as laboratory-based quality control and compliance testing.

3. How does the chamber control and maintain the hydrogen sulfide test environment?

The chamber uses a bottled gas supply system to precisely regulate hydrogen sulfide concentration within the specified range. Temperature is controlled by a high-precision PID microcomputer controller with a resolution of 0.1 °C, while humidity is maintained between 93% and 98% RH. An internal fan and rotary table system ensure uniform gas distribution, allowing all samples to be exposed to consistent corrosive conditions throughout the test duration.