Search keywords:

product name, product type, model number,

test method, manufacturer, technique, application

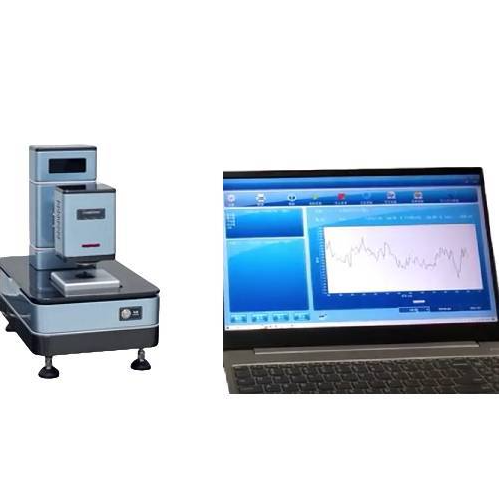

Textile UV Protection Performance Tester

BACKStandards:

GB/T 18830 Textiles - Evaluation of Ultraviolet Protection AATCC 183 Transmission or Blocking of Erythema-Weighted Ultraviolet Radiation Through Textiles BS 7914 Standard Test Method for Ultraviolet Protection of Textiles EN 13758-1 Test Methods for Ultraviolet Protection of Apparel Fabrics AS/NZS 4399 Sun Protection Clothing: Evaluation and Classification - Textile UV Protection Performance Test JIS L1925 Determination of Ultraviolet Shielding Factor of Textile Products

Applications:

Textile UV Protection Performance Tester is used to evaluate the ability of textiles, fabrics, and other materials to protect against ultraviolet radiation from sunlight under specified conditions.

Product Information:

The Textile UV Protection Performance Tester is a high-precision optical instrument designed to evaluate the solar ultraviolet radiation protection properties of various materials under standardized conditions. By utilizing a stabilized xenon arc lamp and a high-sensitivity photomultiplier tube (PMT),

Features

1. Utilizes xenon arc lamps as light sources with high-sensitivity PMT processing

2. Fully computer-controlled with automatic data processing and storage

3. Multiple graphical representations, statistical reports, and analysis capabilities

4. Application software incorporates pre-programmed solar spectral radiation factors and CIE spectral red spot response factors for precise calculation of sample UPF values

Parameters

| No. | Item | Specifications |

|---|---|---|

| 1 | Detection Wavelength Range | (290 ~ 400) nm, accuracy: 0.2% |

| 2 | Wavelength Repeatability | 0.25 nm |

| 3 | SPF Test Range | 1–50+ |

| 4 | Wavelength Interval | 1 nm, 2 nm, 5 nm |

| 5 | Sample Positioning | Fully automatic X-Y positioning |

| 6 | Test Results | COLIPA/ISO in vitro method for UVA-PF/SPF ratio |

| 7 | Power Supply | 220V, 50Hz, 125W |

| 8 | Weight | Approximately 40 kg |

Accessories

1. Host computer 1 unit

2. Computer 1 unit

3. Inkjet printer 1 unit

4. Connection software 1 set

5. USB communication cable 1 piece

6. Product certificate of conformity 1 copy

7. Product user manual 1 copy

8. Delivery note 1 copy

9. Acceptance form 1 copy

Test Procedures

1. System Initialization

Power on the instrument and the computer. Allow the xenon arc lamp to stabilize for the recommended warm-up period to ensure consistent irradiance output. Launch the analysis software and select the desired testing standard (e.g., GB/T 18830).

2. Calibration and Zeroing

Perform a baseline scan with an empty sample holder to calibrate the system's $100\%$ transmittance reference. This compensates for ambient conditions and current lamp intensity.

3. Sample Preparation and Loading

Cut the textile sample into the required dimensions, ensuring it is flat and free of wrinkles. Place the sample into the holder. The automatic X-Y positioning system will align the sample for the first measurement point.

4. Measurement and Data Acquisition

Initiate the scan. The instrument will measure the spectral transmittance at specified intervals (e.g., $2\text{ nm}$) across the $290\text{--}400\text{ nm}$ range. The software will repeat this process for different points on the fabric as required by the standard.

5. Report Generation

The software automatically calculates the mean UPF value, UVA transmittance, and UVB transmittance. You can then save the data to the database and print the standardized test report.

Conclusion

The Textile UV Protection Performance Tester provides an accurate and standardized solution for evaluating the ultraviolet shielding capability of textile materials. By combining a stable xenon arc light source, high-sensitivity optical detection, and intelligent data processing, it ensures precise measurement of UV transmittance and reliable UPF calculation. Compliant with major international standards, the system supports consistent quality control, product certification, and R&D of sun-protective textiles. Its automated operation, comprehensive analysis functions, and clear reporting make it an essential tool for assessing and improving UV protection performance in fabrics and related materials.

FAQ

1.How does the erythema response factor affect the final UPF calculation?

The erythema response factor weights the UV wavelengths based on how much damage they cause to human skin. Since the skin is more sensitive to certain wavelengths (primarily in the UVB range), the software applies these weights to the measured transmittance to provide a UPF value that accurately reflects biological protection.

2.Why is it necessary to measure multiple points on a single piece of fabric?

Fabric density and pore size can vary slightly across a roll of material. By using the automatic X-Y stage to measure at least four different points, you obtain a statistically significant average that accounts for the inherent non-uniformity of woven or knitted structures.

3.Can this instrument measure the UV protection of wet or stretched fabrics?

Yes. While standard tests are performed in a dry, relaxed state, many international standards (like AS/NZS 4399) recommend testing under "stretched" or "wet" conditions to simulate real-world use. You can adapt your sample preparation to meet these specific requirements before placing them in the holder.

4.What is the difference between SPF and UPF in the context of this tester?

SPF (Sun Protection Factor) is traditionally used for sunscreens applied to the skin, while UPF (Ultraviolet Protection Factor) is the standard term for fabrics. This tester calculates the UPF of the fabric, which indicates how much longer it takes for skin under the fabric to burn compared to unprotected skin.

5.How often should the wavelength accuracy be calibrated?

Wavelength accuracy is critical for the precision of the UV protective rating. It is recommended that you perform a wavelength verification every six months or after the lamp is replaced, using a standard reference material with known transmittance peaks.