Search keywords:

product name, product type, model number,

test method, manufacturer, technique, application

Martindale Abrasion Tester

BACKStandards:

ASTM D4970, ISO 12945.2, GB/T 4802.2/13775/21196.1/21196.2, ASTM D4966, ISO 12947, FZ/T 20020, BS 3424-24/5690, ISO 12947.1/12947.2, M&S P17/P19/P19C, NEXT 18/18a/18b, ISO 5470-2, IWTO-40, JIS L1096 8.17.5 Method E, Woolmark TM 112/196, BS EN 388/530/13770, ISO 20344

Applications:

To determine the abrasion and pilling resistance of all kinds of textile structures.Samples are rubbed against known abradents at low pressures and in continuously changing directions and the amount of abrasion or pilling is compared against standard parameters. Provided with Touch Screen Controller and unique programmer which includes preprogammable batch and totaliser counters, individual station counters, 4 selectable test speeds with liquid crystal display.

Product Information:

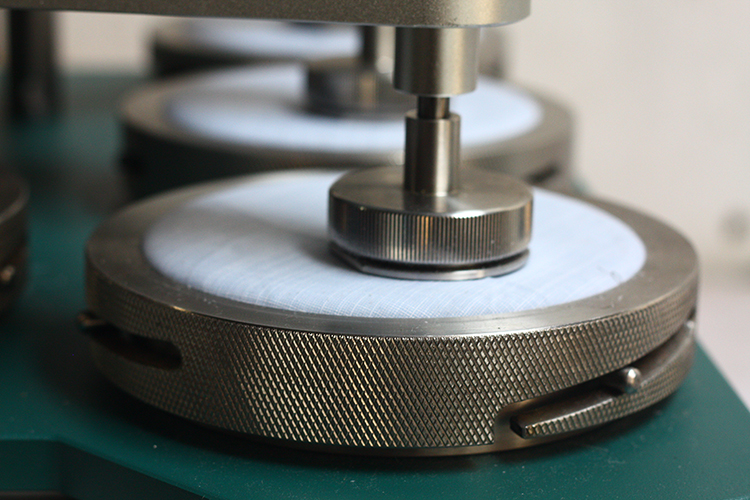

Martindale Abrasion And Pilling Tester

Martindale Abrasion & Pilling Tester. To determine the abrasion and pilling resistance of all kinds of textile structures. Samples are rubbed against known abrasives at low pressures and in continuously changing directions. The amount of abrasion or pilling is compared against standard parameters.

The unique design of our Martindale abrasion tester allows removal of individual sample holders for examination without lifting the top motion plate. It provides individual counters and parking function, interval time settable and a large touch-screen display. Standard sample holders and 9 and 12kpa Weights are included.

The Martindale abrasion tester is available with 4. 6. 8 or 9 test positions.

Martindale abrasion tester working principle:

Test piece of fabric is placed in the specimen clamp, and it will be rubbed against with abradant in a Lissajous figure. According to the requirement, once the test piece is broken, test piece should be taken down to calculate its abrasion resistance index, or evaluate its rating of pilling through the visual description.

Product Information:

The instrument is professionally designed to determine the abrasion and pilling resistance of all kinds of textile structures.

Samples are rubbed against known abradents at low pressures and in continuously changing directions and the amount of abrasion or pilling is compared against standard parameters.

Provided with Touch Screen Controller and unique programming device which includes preprogammable batch and totaliser counters, individual station counters, 4 selectable test speeds with liquid crystal display.

Technical Parameters:

1.Test positions: 9;

2.Count range: 0~999999;

3.Maximum stroke: horizontal 60.5±0.5mm, longitudinal 24±0.5mm;

4.Weight of pressurized materials:

a.Clamp holder assembly: 200±1g

b.Loading pieces for smaller piece: 395±2g

c.Loading pieces for larger piece: 594±2g

d.Stainless steel piece: 260±1g

5.Additional loading weight valid abradent diameter:

Type A 200g(1.96N) Pressure(9KPa) ¢28.8-0.084mm

Type B 155g(1.52N) Pressure (12KPa) ¢90-0.10mm

6.The relative speed with Clamp holder and Abrading table: 20-70r/min(Adjustable);

7.Weight of ample loading hammer: 2385±10g.

Instrument Configurations and Consumables:

1.Specimen holder assembly of 9 sets;

2.9kPa, 12kPa additional loading weight , each of 9;

3.¢38mm, ¢140mm Abradent Fabric/Backing Felt cutter of 1 set;

4.¢38mm, ¢140mm test specimen cutting mat of 1 set;

5.Pilling Test Suite of 1 set;

6.SM-50 Photographs for pilling test of 1 set;

7.EMPA Photographic Standards for Pilling Test of 1 set, and SM-25 Standard Abradent Fabric of 1.6m×5m;

8.Standard Backing Foam. Width of 1.5m, Length of 0.5m. Pack of 4;

9.Standard Backing Felt Piece of 1;

10.¢90mm Standard Backing Felt Discs(Pack of 20);

11.¢38mm, ¢140mm spare blades of specimen cutter, 50 each;

12.Other necessary accessories recommended by manufacturer.

Specifications:

Drive system is PLC, programmable control with large touch-screen

①、Abrasion test

Max stroke of movement 5+/-0.5mm

Weight of holder and spindle 200+/-1g

②、Pilling test

Max stroke of movement 24+/-0.5mm

Weight of holder and spindle 155+/-1g