What are the different types of pilling tests?

2023/11/16

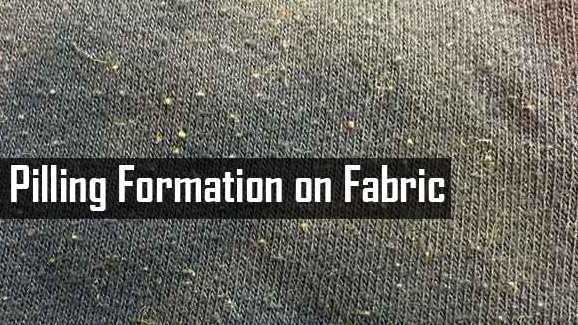

There are several methods and tests used to assess the propensity of textiles to develop pills, which are small, tangled fiber clusters on the surface of fabric. Different types of pilling tests help manufacturers and researchers evaluate the durability and wear resistance of textiles. Here are some common types of pilling tests:

Martindale Pilling Test (ISO 12945-2):

-

Purpose:

- Evaluate the resistance of textiles to pilling and abrasion.

-

Procedure:

- Specimens are mounted on the Martindale abrasion tester.

- Abrasive action is applied through the use of rubbing discs or pads.

- The test is conducted for a specified number of cycles.

-

Evaluation:

- The extent of pilling is visually assessed using a grading system.

ICI Pilling Box Test (ISO 12945-1):

-

Purpose:

- Assess the propensity of textiles to form pills due to rubbing.

-

Procedure:

- Samples of fabric are placed in a box and subjected to controlled rubbing using cork liners.

- The test is conducted for a specified duration.

-

Evaluation:

- The samples are evaluated for pilling visually, and results are graded according to established criteria.

Random Tumble Pilling Tester (ASTM D3512):

-

Purpose:

- Simulate pilling due to the action of fabric rubbing against itself.

-

Procedure:

- Fabric specimens, along with a specified load of abrasive pills, are tumbled in a rotating chamber.

- The test is conducted for a specified duration.

-

Evaluation:

- Visual assessment of pilling is performed, and a rating is assigned based on standardized criteria.

Modified Martindale Pilling Test (ISO 12945-2, modified):

-

Purpose:

- Similar to the Martindale Pilling Test but with modifications for specific applications or requirements.

-

Procedure:

- Variations in test parameters or equipment may be applied based on the specific needs of the evaluation.

These tests help manufacturers ensure that textiles meet certain durability standards and can withstand the mechanical forces that lead to pilling during normal wear and use. The choice of test method often depends on factors such as the type of fabric, end-use application, and industry standards.

Previous: What is ISO 105 E01 test?

N e x t : 6 Methods Of Fabric Testing Standards And The Impact