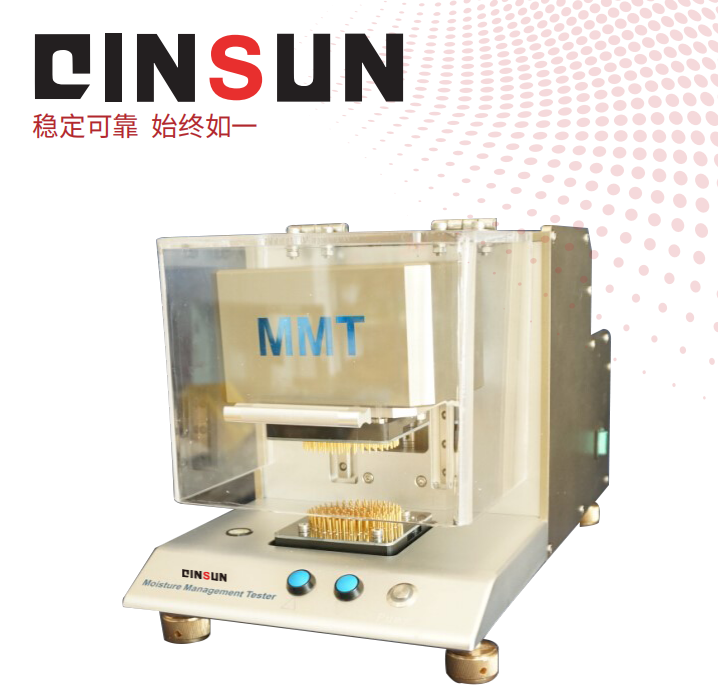

MMT Liquid Water Separation Tester,ISO 4920

2026/02/05

This type of instrument is particularly important in the textile industry because liquid moisture handling directly affects wearer comfort and functional performance, especially in sportswear, high-performance fabrics, and underwear. Traditional absorption tests typically focus only on the amount of liquid absorbed, whereas the MMT emphasizes dynamic transport, reflecting the complete process of liquid movement from the contact side of the fabric through to the interior or outer surface.

Background and Industry Need

In the evaluation system for textile comfort and functionality, liquid moisture management has become a key performance indicator. The movement of liquid within fabrics reflects not only intrinsic absorbency and diffusion but also practical properties such as sweat-wicking, dryness, and evaporative performance—factors directly experienced by consumers of functional textiles, including sportswear and outdoor gear.

The development of instruments capable of precisely measuring the dynamic movement of liquid through textiles emerged to satisfy the need for objective, standardized testing. MMT instruments translate subjective perceptions of liquid transport into quantifiable metrics, providing a solid foundation for textile quality control, research and development, and competitive evaluation.

Standards and Testing Specifications

Moisture management testing is referenced in several international and national standards, the most commonly cited include:

AATCC 195: Widely adopted in the textile industry, specifying test conditions, environment, procedures, and data calculation methods for evaluating liquid moisture management.

GB/T 21655.2 series: The Chinese national standard for textile moisture management testing, sharing similar testing principles and metric systems with AATCC 195.

These standards strictly define sample preparation, instrument setup, and test parameters—such as test liquid conductivity, test duration, and sample dimensions—to ensure reproducibility and comparability of results.

Testing Principle: Quantifying Dynamic Liquid Transport

The core principle of MMT testing is to simulate the dynamic movement of liquid in contact with fabric and monitor liquid diffusion and flow through changes in electrical resistance or conductivity.

Typical procedure:

Sample Placement

The textile specimen is placed horizontally between two sensor arrays. The upper and lower sensors typically consist of concentric circular probes capable of detecting resistance changes upon liquid contact.

Liquid Application

The instrument delivers a predetermined volume of test liquid onto the center of the specimen’s upper surface at a controlled rate. The test liquid is usually a simulated sweat solution with conductivity meeting standard requirements.

Liquid Movement Monitoring

The liquid spreads across the fabric surface and gradually penetrates to the lower surface, also spreading outward along both surfaces. Sensors continuously monitor resistance changes across the fabric area, recording wetting processes, absorption rates, and other key dynamic parameters.

Metrics and Analysis*

The MMT software automatically calculates multiple key metrics that collectively form the fabric’s moisture management “fingerprint”:

Wetting Time: Time for liquid to start wetting the fabric surface, recorded separately for top and bottom layers. Shorter wetting time indicates faster liquid response.

Absorption Rate: Speed at which the fabric absorbs liquid, reflecting fiber and structure capability to handle moisture.

Maximum Wetted Radius: Maximum radius of liquid spread across the fabric surface within a specified time, representing spatial diffusion performance.

Spreading Speed: Rate at which liquid spreads along the fabric surface, related to sweat-wicking efficiency.

One-Way Transport Capacity: Evaluates the tendency and efficiency of liquid transport from the inner to outer fabric layer, a key indicator of wicking performance.

Overall Moisture Management Capacity (OMMC): A composite score derived from all indicators, providing an overall assessment of the fabric’s liquid management performance in practical use.

These metrics support material evaluation, comparison, and optimization of fabric structure and design.

Typical Testing Procedure

Sample Preparation and Conditioning

Samples are pretreated (e.g., washed and dried) according to standard conditions, cut to standard dimensions, and laid flat without tension.

Test Liquid Preparation

A simulated sweat solution is prepared with conductivity adjusted to the standard range (e.g., 16 ± 0.2 mS/cm).

Instrument Setup

The sample is mounted between the sensor arrays. Test parameters, such as duration (e.g., 120 s) and droplet volume, are configured. The instrument automatically applies load pressure and maintains it during testing.

Test Execution

The test liquid is evenly applied to the sample, and sensors detect resistance changes in real time. Data are recorded and analyzed simultaneously.

Data Output and Analysis

After testing, the software generates a report including all key metrics for comparison, rating, and research purposes.

Applications and Value

Textile Comfort Assessment:

MMT provides objective evaluation of wetness perception and moisture transport, critical in sportswear, functional underwear, and infant clothing, directly influencing wearer experience.

Functional Textile R&D:

Indicators generated by MMT help researchers quickly screen materials and fine-tune absorption, wicking, and drying properties in new fibers, fabric structures, and finishing technologies.

Quality Control and Product Classification:

MMT can be integrated into production quality control, ensuring batch-to-batch consistency, and enabling product classification for consumers based on moisture management performance.

Standards Development and Academic Research:

Test data from MMT instruments contribute to the formulation of textile testing standards and provide empirical support for scientific studies on liquid transport mechanisms.

Technical Advantages and Future Trends

Comprehensive Dynamic Analysis: Unlike traditional absorption tests, MMT captures multiple dimensions of liquid-fabric interaction. The OMMC score provides an overall performance metric.

Automated Data Processing: Modern instruments include automated control and data analysis software, enabling one-touch testing and standardized reporting.

Standard Compatibility and Global Relevance: Test results align with international standards, facilitating product comparison and market acceptance.

Future Development:

With increasing innovation in functional textiles and personalized requirements, MMT may integrate AI analytics, cloud-based databases, and advanced modeling to provide smarter, more detailed evaluations, enabling refined assessment of fabric performance.

The Moisture Management Tester (MMT) is an essential instrument for evaluating dynamic liquid transport in textiles. Through standardized methods and precise metrics, it provides reliable support for comfort evaluation, functional textile development, quality control, and standardization. As demand for high-performance fabrics grows, the importance of MMT will continue to increase, driving the textile industry toward more efficient, scientific, and performance-driven solutions.

Previous: Dental material color stability tester,YY0270.1-2011

N e x t : the last page