What is the drying rate test?

2026/02/06

Basic Definition and Significance

Drying rate testing refers to an experimental technique used to measure the rate at which a textile loses moisture under specified conditions. Simply put, it evaluates how quickly water evaporates from a fabric after it has been wetted, under controlled environmental factors such as heat and airflow. The “rate” is typically expressed as the percentage of moisture loss per unit time or the total time required for complete drying.

The significance of drying rate testing lies not only in the scientific quantification of fabric performance, but also in its ability to help textile researchers, quality managers, and product designers determine whether a fabric performs as expected in real wearing scenarios, such as perspiration or exposure to rain. For next-to-skin products such as sportswear, underwear, and socks, quick-drying performance directly affects wearer comfort and overall well-being.

Therefore, drying rate testing provides quantitative performance data and serves as an essential technical foundation for product innovation, raw material selection, finishing process optimization, and functional textile differentiation in the consumer market.

Scientific Principles

At its core, the drying rate represents the rate of moisture evaporation. After a fabric absorbs moisture, the movement of water from within the fibers to the surrounding air is influenced by multiple factors, including fiber type, fabric structure, surface finishing processes, and ambient temperature and humidity. Drying rate testing simulates this evaporation process by precisely measuring changes in residual moisture over time under controlled conditions, allowing the evaporation speed and total drying time to be determined.

In general, drying rate testing is based on the following principles:

Moisture application: A precise volume of water is applied to the fabric sample or the sample is brought to a defined wet state.

Controlled environment: The sample is placed in a standardized environment with fixed temperature, airflow, and air velocity.

Evaporation monitoring: Moisture loss is tracked through weight measurements, temperature sensors, or continuous mass-change recording.

Rate calculation: Moisture retention versus time curves are generated, and statistical or linear regression methods are used to calculate drying rate and drying time.

In certain heated plate drying rate tests, samples are placed on a heated surface maintained at approximately skin temperature (around 37°C) to simulate the evaporation of sweat between fabric and human skin.

Overall, the essence of drying rate testing lies in controlled variables, precise measurement, and statistical analysis, ensuring that drying behavior can be reliably compared among different fabric samples under identical test conditions.

Main Drying Rate Test Methods

Drying rate testing does not rely on a single method but encompasses several standardized approaches, each suited to specific equipment and evaluation objectives. The most commonly used methods include the following:

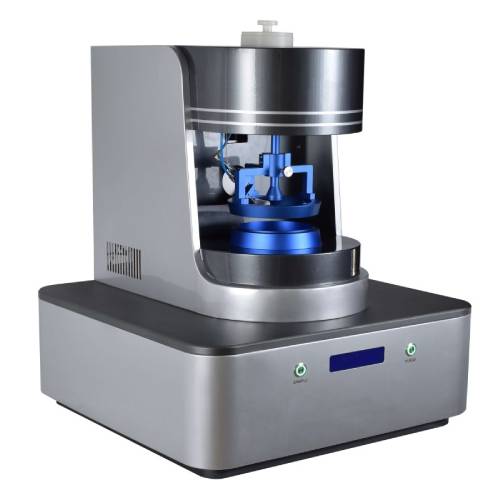

(1) Heated Plate Method

The heated plate method is one of the most widely used drying rate testing approaches. In this method, a fabric sample is placed on or attached to a temperature-controlled heating plate, and a specified volume of water is applied beneath or within the sample. The evaporation process is then monitored under controlled airflow conditions to assess the fabric’s moisture evaporation performance.

Typically, the heating plate is set to approximately 37°C to simulate human perspiration conditions, while airflow speed is controlled to maintain stable evaporation. The testing system continuously monitors moisture content, temperature, and mass changes, allowing the drying rate to be calculated. This method complies with established test standards and is widely recognized for evaluating quick-dry performance in textiles.

(2) Air Flow Drying Method

The air flow drying method evaluates drying behavior by exposing a wetted fabric sample to a controlled airflow environment without direct heating or with minimal heating assistance. The drying rate is determined by measuring the reduction in sample weight over time.

This method places greater emphasis on the influence of airflow on evaporation and is often used to analyze the relationship between fabric structure and moisture evaporation performance.

(3) Standardized International Measurement Methods (ISO Drying Tests)

International standards such as ISO 17617:2014 provide a more standardized and detailed framework for drying rate testing of textiles. These standards specify test conditions, sample preparation, environmental controls, moisture application procedures, evaporation measurement methods, and data analysis requirements, ensuring high reproducibility and comparability of results.

ISO standards define multiple testing configurations, including horizontal placement and vertical suspension of samples. Drying rate and time to complete dryness are typically calculated using linear regression or statistical analysis, transforming experimental data into scientifically meaningful indicators.

Experimental Standards for Drying Rate Testing

To ensure accuracy, comparability, and repeatability, drying rate testing follows various international and association standards, including:

1. AATCC Standards

The American Association of Textile Chemists and Colorists (AATCC) has established drying rate test methods such as AATCC Test Method 201 (heated plate method) and AATCC TM200 (air flow drying method). The heated plate method is primarily used to evaluate drying performance under simulated sweat and body temperature conditions, while the air flow method focuses on overall drying behavior.

2. ISO 17617 Standard

ISO 17617:2014 is an international standard that defines test procedures for evaluating textile moisture drying rates. It specifies environmental conditions, sample preparation, moisture application, and result analysis, creating a unified global evaluation framework for drying performance.

3. Other Relevant Standards

Additional standards address specific fabric thicknesses, end-use applications, or testing considerations, making drying rate testing more targeted and adaptable to different textile categories.

Key Indicators and Calculation Methods

Drying rate testing typically produces the following core indicators:

Drying Rate

Drying rate is commonly expressed as the percentage of moisture loss per unit time (e.g., % per minute). It reflects how quickly a fabric dries under specified conditions and is a primary indicator of quick-dry performance.

Drying Time

Drying time refers to the total duration required for a fabric to reach complete dryness, often defined as the time needed for 100% moisture loss. This parameter reflects the overall efficiency of the drying process.

In standardized testing, time is plotted on the horizontal axis and residual moisture or sample weight on the vertical axis. Linear regression or statistical analysis is then used to determine drying rate and total drying time.

Factors Affecting Drying Rate Test Results

Drying rate is not a fixed value and is influenced by multiple factors:

1. Fiber Type

Different fibers exhibit distinct moisture absorption and evaporation behaviors. Synthetic fibers such as polyester and nylon typically absorb less moisture and dry faster, while natural fibers such as cotton absorb water internally and tend to dry more slowly.

2. Fabric Structure and Density

Weave type, porosity, and capillary structure directly affect moisture transport pathways. Looser fabrics may allow faster moisture diffusion, while denser fabrics may exhibit more efficient evaporation and reduced rewetting behavior.

3. Environmental Conditions

Temperature, humidity, and airflow significantly influence evaporation. High temperature, low humidity, and strong airflow accelerate drying, whereas opposite conditions slow the process.

4. Finishing Processes

Special finishes such as hydrophobic or hydrophilic treatments, nanotechnology-based coatings, and functional surface modifications alter fiber–water interactions and directly impact drying behavior.

Practical Applications of Drying Rate Testing

Drying rate testing is widely applied across the textile industry:

(1) Development and Optimization of Performance Textiles

In the development of sportswear and outdoor apparel, drying rate serves as a key indicator for selecting raw materials, optimizing fiber blends, and refining fabric structures to achieve rapid moisture evaporation.

(2) Quality Control and Consistency Evaluation

Drying rate testing is used to verify batch-to-batch consistency, ensuring stable quick-dry performance that meets design specifications and market expectations.

(3) Market Positioning and Performance Claims

For sports brands and high-performance garments, drying performance is often a major selling point. Scientifically measured drying rate data provide objective support for marketing claims and consumer evaluation.

(4) Standardized Certification and Benchmarking

Testing conducted in accordance with international or association standards ensures global comparability of performance data, supporting export requirements and industry certification.

Scientific Evaluation of Drying Rate Test Results

When interpreting drying rate test results, several considerations are essential:

Consistency of environmental conditions: Results obtained under different conditions cannot be directly compared.

Uniformity of sample preparation: Variations in sample size, fiber orientation, or moisture application affect accuracy.

Data analysis methods: Standardized statistical approaches, such as linear regression, should be used to ensure meaningful indicators.

Correlation with real wear conditions: Laboratory results should be interpreted alongside real-world usage scenarios rather than relied upon in isolation.

Drying rate testing is a critical component of textile performance evaluation systems. It quantifies the speed and efficiency of moisture loss after wetting and serves as a core technical method for assessing quick-dry functionality. This article has provided a comprehensive overview of drying rate testing from definitions and principles to methods, standards, influencing factors, and applications.

By adopting standardized international testing methods, drying rate testing delivers reliable scientific data that support textile design, quality control, market communication, and technological innovation. As consumer demand for comfort and functional performance continues to grow, the importance of drying rate testing in the textile industry will become increasingly significant.

Previous: What is the strength test for fabric?

N e x t : the last page