Tear strength to evaluate fabric resistant to tear

2019/08/02

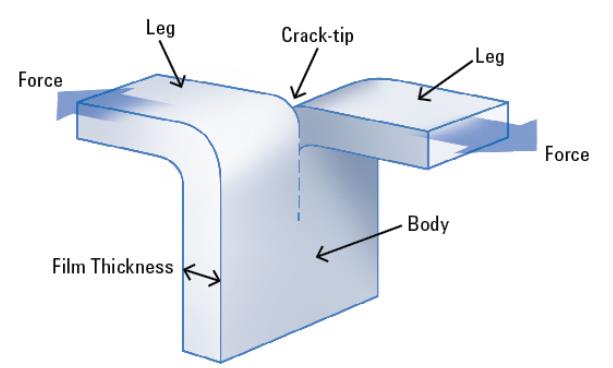

Tear strength is used to evaluate the ability of fabric resistant to tear along the breach or damaged position in the process of use. Its unit is Newton, “N” for short. Generally, tear strength determines the durability of dyeing and finishing products. A part of fabric edge is applied a centered load, to make each inner yarn undertake maximum load to burst, and at last a crack comes. Tear strength is often used to measure the performance of tent and umbrella, but knitting fabric and elastic woven fabric will not test this indicator.

How to Calculate Tear Strength

Most companies that conduct tear strength tests use machines where tears are done at specific levels of force through different sample thicknesses to assure that they are up to the demands placed upon the product.

-Determine the amount of force. This should be in the standard measure of Newtons. (Force is calculated by multiplying mass by acceleration, F = ma.)

For example: Force = 28.5 N

-Determine thickness of sample used. This can be in millimeters (mm), centimeters (cm), inches (inch), meters (m), etc.

For example: t = 7.2mm

-Divide the amount of force by the thickness of the sample. The result will be measured in Newtons per unit of thickness.

For example: 28.5 N/7.2mm = 3.9583 N/mm

Previous: Main methods and tests for measuring fabric abrasion

N e x t : Understanding the Fabric pilling