NewsInformation Center

ASTM F2100 :Five Performance Requirements For Medical Face Masks

2020/06/11

ASTM F2100-19 is intended for use by those constructing medical face masks. Specifications developed by the American Society of Testing and Materials (ASTM) in 2004 are referenced by the FDA as the required standard in the USA. This standard does not apply to regulated respiratory protection, nor does it cover medical face masks for all possible use situations. For example, as stated in the ASTM F2100-19 document, “the Centers for Disease Control and Prevention (CDC) specifically requires NIOSH respirators that are at least 95% efficient for tuberculosis exposure control.”

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

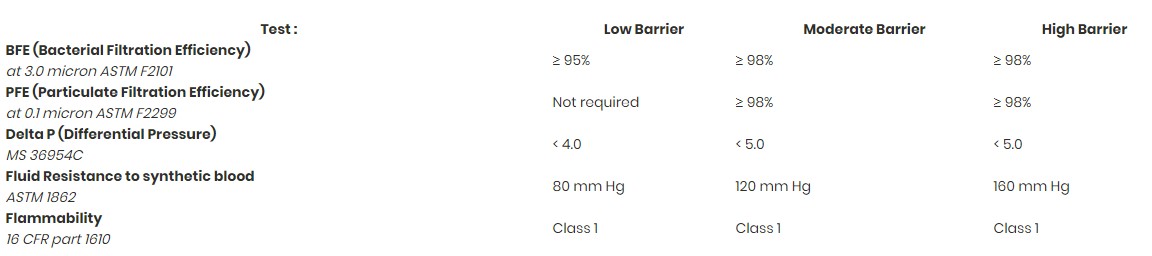

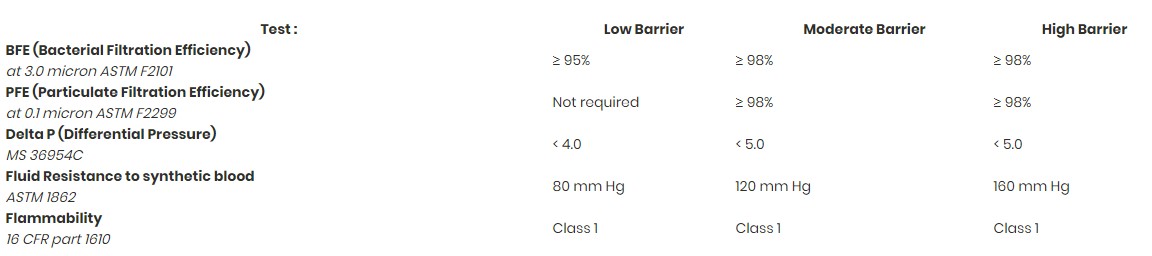

The current standard ASTM F2100 specifies the performance requirements for Medical Face Masks with five basic criteria:

BFE (bacterial filtration efficiency) measures how well the mask filters out bacteria when challenged with a bacteria-containing aerosol. ASTM specifies testing with a droplet size of 3.0 microns containing Staph. aureus (average size 0.6-0.8 microns). In order to be called a medical/surgical mask, a minimum 95% filtration rate is required. Moderate and high protection masks have bacterial filtration rates of 98% to greater than 99%.

PFE (particulate filtration efficiency) evaluates the nonviable particle retention or filtration efficiency of filter media and other filtration devices at sub-micron levels. The higher the percentage, the better the mask efficiency. Although testing is available using a particle size from 0.1 to 5.0 microns, ASTM F2100-07 specifies that a particle size of 0.1 micron be used.

Fluid Resistance reflects the mask's ability to minimize the amount of fluid that could transfer from the outer layers through to the inner layer as the result of a splash or spray. evaluates the resistance of a medical face mask to penetration by a small volume (~2 mL) of synthetic blood at a high velocity (80 mmHg, 120 mmHg, or 160 mmHg). The mask either passes or fails based on visual evidence of synthetic blood penetration.

Delta P (pressure differential) measures how easily air is passed from one side of the mask to the other. This indicates how easily the wearer can breathe through the mask, and is in indicated by Delta P. Higher DP indicates air is more difficult to push through.

Flammability: Operating rooms contain sources of oxygen and other gases used for anesthesia, and there are potential fire hazards from electrosurgical procedures such as lasers or cautery equipment. This test exposes the face mask material to a flame and measures the time required for the flame to proceed up the material a distance of 127 mm (5 inches). Class 1 means the material exhibits normal flammability and is acceptable for use in clothing.

Previous: How To Produce Good Meltblown Nonwoven Masks

N e x t : What Is The Specialty of N95 Masks ?