NewsInformation Center

Analysis mask filtration efficiency tester

2021/10/13

Medical masks are classified into medical protective masks, medical surgical masks and ordinary medical masks according to their intended use, as detailed below.

1. Medical protective mask

Medical protective masks are masks made of one or more fabrics that have an isolation effect on virus qi sol, virus-containing liquids, etc., which still have a barrier effect on virus qi sol, virus-containing liquids, etc. under the breathing airflow, and are removed At this time, the outer surface of the mask is not in contact with the human body and is worn on the face of the person in contact with the viral material in the medical institution to prevent the virus from the patient from spreading to the medical staff.

2. Medical surgical masks

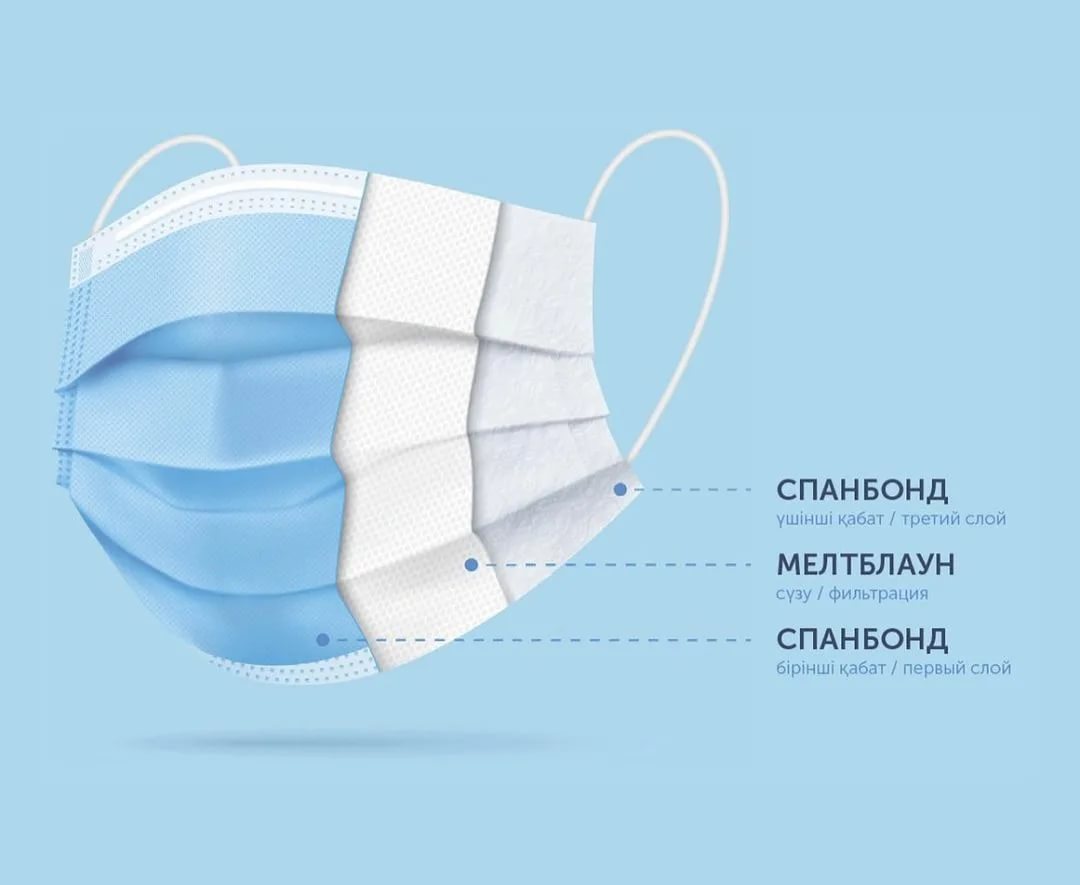

Medical surgical masks are usually made of masks, shaped parts, straps and other components. They are generally made of non-woven materials. They are isolated by filtration. They are used to wear on the mouth and nose of medical staff in the operating room to prevent skin damage. Debris and respiratory tract microorganisms spread to open surgical wounds, and prevent the body fluids of surgical patients from spreading to medical staff, playing a two-way biological protection role.

3. Ordinary medical masks

Ordinary medical masks are used to cover the mouth, nose, and jaw of users, and are used in ordinary medical environments to block pollutants exhaled or sprayed out of the oral cavity and nasal cavity. Disposable medical masks are suitable for the wearer's health care in ordinary medical environments where there is no risk of body fluids and splashes.

Mask filtration efficiency testers mainly include particulate matter filtration efficiency testers and bacterial filtration efficiency testers. They are used to test disposable medical masks, medical surgical masks, ordinary masks and other daily protective masks, as well as the particulate matter and meltblown cloth used in the production of masks. Bacteria filtration efficiency.

Applicable standards:

GB19083 Technical requirements for medical protective masks

GB2626 self-priming filter anti-particulate respirator

GB32610 Technical Specification for Daily Protective Masks

GB19082 Medical disposable protective clothing

YY0469 medical surgical mask

YY0969 disposable medical mask

NIOSH42CFRPart84 respiratory protection device

EN143 Respiratory Protector. Particulate Filter. Requirements and Inspection

JMOL Japan Standard for Protective Masks

The degree of protection of medical masks:

1. Medical protective mask

According to the filtering efficiency of the mask for non-oily particles when the gas flow rate is 85L/min, medical protective masks are divided into three protection levels:

2. Medical surgical masks

The protection level is not divided.

It is stipulated that the bacterial efficiency of masks should not be less than 95%, and the filtration efficiency of masks for non-oily particles should not be less than 30%.

3. Ordinary medical masks

The protection level is not divided.

It is stipulated that the bacterial efficiency of masks should not be less than 95%.

The above is the detailed content of the detailed answer of the Standard Group for you. I hope to help you. Of course, if you want to buy a product, you are welcome to consult: 13671849966.

Previous: Comprehensive analysis of filter material dynamic and static filtration efficien

N e x t : Jordan's garment and textile industry is facing serious difficulties