NewsInformation Center

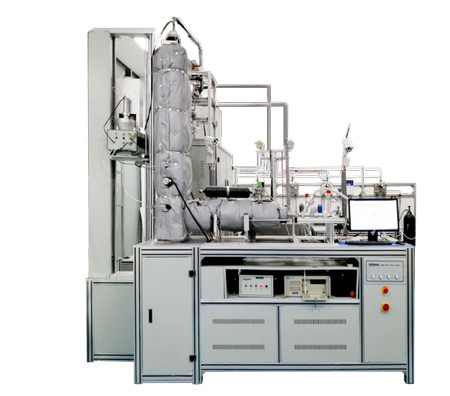

16 technical parameters of Filter Material Dynamic Filtering Performance Tester

2021/11/08

Filter Material Dynamic Filtering Performance Tester is suitable for medical device inspection centers, safety protection inspection centers, labor protection inspection centers, drug inspection centers, disease prevention and control centers, textile inspection centers, hospitals, masks and respirator manufacturers, etc.

technical parameter:

1. The cold-generating aerosol generator is used to produce continuous and stable aerosol particles, which is convenient for filling the solution.

2. The high-precision PM2.5 sensor is used to measure the aerosol concentration.

3. The whole process of particle leakage prevention design protects the safety of experimenters.

4. 2 sets of aerosol generators: salt particulate aerosol generator and oil particulate aerosol generator.

5. Equipped with aerosol particle electrostatic charge neutralization device.

6. Equipped with temperature and humidity sensors, real-time display of environmental temperature and humidity (temperature and humidity requirements: 25℃±5℃, 30%RH±10%RH).

7. Configure laser dust particle counter.

8. The front door of the protective effect test chamber is designed with good airtightness. It is equipped with operating gloves to facilitate the replacement of the mask to be inspected.

9. The protective effect test adopts a standard head model: 1 standard head model, imitating the real situation of people wearing protective masks.

10. Protective effect Aerosol particles: the concentration range of the test chamber (20-30) mg/m3, adjustable settings, the concentration fluctuation is less than ±10%; the aerosol generator produces a particle size distribution of 0.02-2μm, and the mass median diameter: salt The particles are 0.6μm and the oil particles are 0.3μm.

11. Protection effect. Aerosol concentration detection device: gas sampling flow (1-2) L/min, sampling frequency: 20 times/min (1-9999 times/min can be set arbitrarily), dynamic detection (0.001-100) mg/ m3, accuracy 1%.

12. Protective effect The inhalation gas sampling tube is directly under the nostril (in the mouth).

13. The protective effect adopts a breathing simulator to simulate the breathing state of the human body.

14. Breathing simulator: sinusoidal air flow, frequency 20 times/min, breathing flow control (30±1) L/min, flow range of respirator: 0-40L/min.

15. Instrument accuracy level (precision level): Level 1

16. Control system: The computer controls the test process, automatically collects data, configures the computer and test software.

Meltblown cloth PFE filtration efficiency meter is used to test the protective effect of daily protective masks and other types of masks on particulate matter. Applicable to medical device inspection centers, safety protection inspection centers, labor protection inspection centers, drug inspection centers, disease prevention and control centers, textile inspection centers, hospitals, masks and respirator manufacturers, etc.

Filter Material Dynamic Filtering Performance Tester is used to test the protective effect of daily protective masks and other types of masks on particulate matter.

Previous: The secret of artificial weathering test

N e x t : Test method of zipper load pull test machine