NewsInformation Center

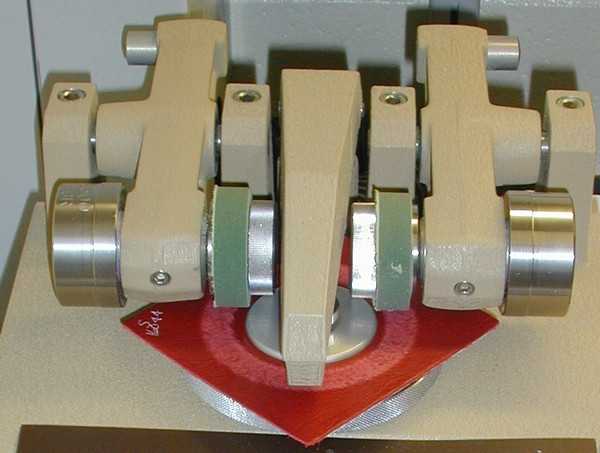

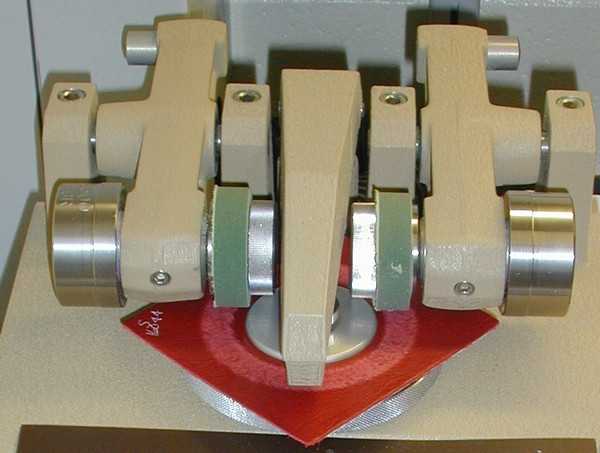

Evaluation of Wear Resistance using Taber Abrasion Tester

2023/03/29

The Taber type abrasion tester is a device used to evaluate the wear resistance of materials by simulating real-world wear conditions, such as abrasions caused by mechanical friction, abrasive wear or other repeated wear. The tester uses a rotating test wheel with abrasive materials that are applied at a specific pressure to the surface of the test sample to determine its durability or resistance to wear.

The Taber type abrasion tester is widely used for testing a variety of materials including plastics, coatings, laminates, metals, rubbers, paints, textiles, leather and other types of products. It is commonly used in quality control testing in manufacturing, research and development settings and in industries that depend on wear-resistant materials such as automotive, aerospace, construction, and consumer products.

The Taber type abrasion tester can also perform different types of abrasion tests including rotary platform abrasion, scuffing resistance, scratch resistance, and many other customizable tests. This versatile testing equipment makes it possible to accurately simulate, quantify, and compare the wear resistance of various materials under different conditions.

Advancements in materials science have led to the development of newer, more precise, and user-friendly Taber type abrasion testers, such as those that integrate the use of lasers and digital cameras to precisely measure the amount of wear on the test samples. Additionally, new software tools have been developed that allow for automated measuring and quick analysis of test results, allowing for more efficient and accurate testing.

Overall, the Taber type abrasion tester plays a critical role in evaluating and ensuring the quality, durability, and wear resistance of a wide range of materials, helping to ensure that they meet the requirements of their intended use and remain reliable over their lifespan.

Previous: What equipment is needed for zipper testing?

N e x t : Mali's cotton production becomes Africa's top producer