NewsInformation Center

10 Ways To Improve Zipper Tester

2023/05/23

Zipper products are widely used in clothing, shoes and hats, bags, tents, etc. Zipper can be repeatedly pulled together and pulled apart, and is a joint consisting of two flexible, single-sided teeth that can be engaged with each other.

Zipper design principle is very unique and ingenious, with the improvement of Zipper production technology, Zipper product applications are expanding, in the field of environmental protection, protective products, cover products, as well as military, medical and health and other aspects of use, with the continuous adoption of high-tech achievements, Zipper functional development prospects are very broad, and its The decorative function in some aspects will also exceed its practical function.

Zipper's strength testing items are more, this paper to explain the flat pull strength testing.

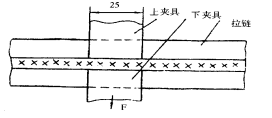

Test equipment and fixture: The test equipment consists of upper and lower fixture, transmission components and force display system. Test range 2000N, test speed ( 300± 10) mm / min. Test equipment accuracy is ± 0. 5% FS (full scale). Main dimensions of the fixture, width 25mm, clamping

The clamping surface teeth angle 60 °, pitch 1. 5 mm, top width 0. 2 mm. two pieces of engagement clamping mouth to the inner teeth 3 mm to be machined into a plane 0. 5 mm below the tooth surface. The clamping screw is M8.

Test method and procedure of flat pulling strength: Take a section of Zipper with length more than 100mm and clamp it in the above fixture. When clamping, the chain tooth foot and the clamped part of the jig should be aligned tightly (Figure 1). Start the tester and test until the teeth are removed or the ribbon is broken, the value recorded at this time is the flat pulling strength value.

2. Single tooth displacement test

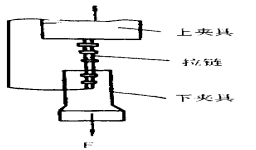

Test equipment and fixture: Test equipment, test speed and test strength of the same conditions. The upper fixture is used to measure the strength of the fixture, and the lower fixture is used to insert a 12-mm diameter jig, as shown in Figure 2.

Test procedure: Take a section of zipper with length more than 50mm and cut it flush. Starting from the shear, remove the two chain teeth, leaving the third tooth (two single piece of the same practice, the chain teeth must not damage the ribbon, not touch the adjacent chain teeth). Start the tester, measured until the teeth off, and record the value, take the arithmetic mean of the single tooth strength of the two single piece that is the single tooth shift strength value.

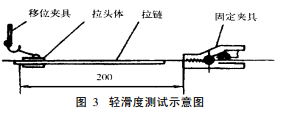

3. Light slippage test

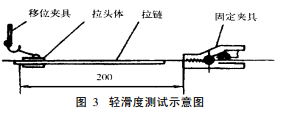

Test equipment and fixture: Test equipment consists of test platform, shift fixture, screw drive system and measurement number display system. Test range is not more than 20N, test speed 1200 ~ 1300mm / min, equipment accuracy ± 0. 5% FS.

Test procedure: Take a finished zipper with a length of about 200mm, pull it back and forth 3 times manually in the free state, and place it on the horizontal surface of the table in the form of pulling it open, clamp the back end in the fixed fixture, align the lower stop with the mouth of the fixture when it is clamped, and put the ribbon in the fixture gap, and push the zipper along the test direction by hand to make it in the natural state, and then put the flap on the shift fixture (Figure 3). 3). Start the tester (the value of the tester should be reset) and measure to the predetermined length, the maximum value recorded in this process is the value of the light slippage of the zipper.

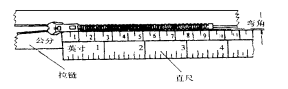

4. Measuring method of zipper length

Measuring tool: Steel ruler with the index value of mm and length of 1m.

Measuring method: Take a finished zipper and place it flat on a flat table, so that it is in a natural state. Use the steel ruler to measure from the top of the zipper to the outer end of the lower stop; the open end of the zipper is measured to the outer end of the socket, and this distance is the length L of the zipper.

5. Test of zipper appearance quality

The test method of zipper dyeing fastness is according to GB3921, and the test of other appearance quality is based on sensory inspection.

6. Test method of zipper straightness

Measurements: 500mm and 150mm steel ruler each, the index value of steel ruler is below millimeter.

Measuring steps: Take a finished zipper and place it flat on a flat table so that it is in the natural state of pulling together, and then move it back and forth once with your fingers along the edge of the chain teeth on both sides. Use a ruler to gradually approach the two ends of the bend, and then use another ruler to measure the maximum distance between the foot of the chain tooth and the ruler (Figure 4). This distance is the maximum bending degree. Value one by one straightness (C-shaped bend height).

Previous: The 10 Best Things About Fabric Perspiration Stain Tester

N e x t : Uv Ageing Test Chamber Shortcuts - The Easy Way