NewsInformation Center

Operation steps of automobile interior material flammability tester

2023/02/03

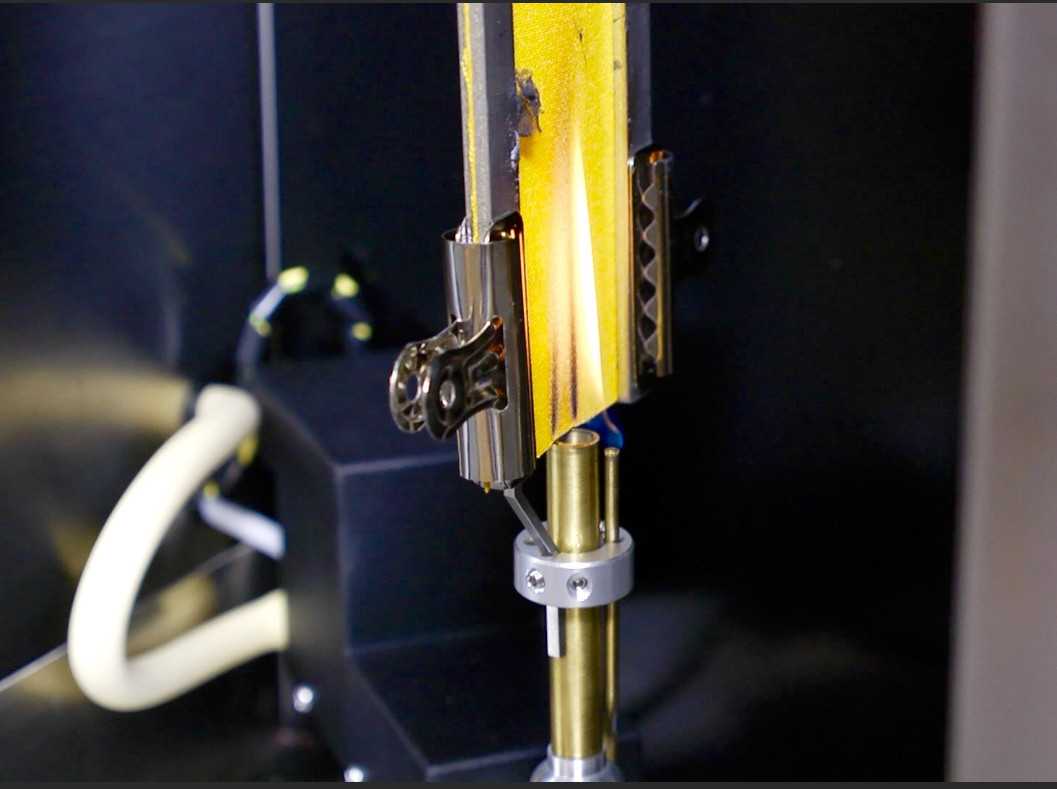

The flammability tester for automobile interior materials is mainly used to qualitatively evaluate the flammability of single materials or laminated composite materials used in automobile interior. It is a test equipment independently developed and produced by Shanghai Qianshi Precision Electromechanical Technology Co., Ltd., with high cost performance and complete after-sales service.

Vertical Flammability Tester scope of application:

Seat cushions, seat backs, seat covers, seat belts, head restraints, armrests, convertible top, all decorative linings, instrument panel, glove box, interior cargo shelf panels, rear sill panels, curtains, flooring coverings etc.

Technical Features:

Equipped with a sealed stainless steel combustion chamber and observation window, made of stainless steel, resistant to high temperature and high pressure; adopts a suspended tympanic membrane structure, with steel springs and a vibration damping system, which can be operated smoothly; equipped with sample clamps and door burners; basic mode Equipped with manual timing control; sample holder can move up and down and left and right; equipped with automatic gas control system including electromagnetic control gas valve, automatic ignition timer and controller.

Procedure:

1. Set the control mode switch to automatic position;

2. Prepare your test sample and install it in the appropriate bracket in the instrument test room;

3. If possible, place the burner under the sample according to your test method;

4. On the AGC, open the main gas shut-off valve by lifting the toggle rod up until the toggle rod is pointing outward from the panel;

Note: Opening this valve allows gas to enter the pilot burner, and the pilot must be ignited immediately;

5. Ignite the pilot burner;

6. Close the instrument room door;

7. Press the timer reset button below the AGC running time display. If the display is counting, press the timer start button to turn it off. Press the timer reset button to display zero;

8. To start the test, press the burner start button and the timer start button on the AGC at the same time. (Correct operation will be indicated by the illumination of both switches.) If neither is lit, press the timer start switch to turn off the light and press the timer reset button below the runtime display. Press both start switches again at the same time to start the test.

Vertical Flammability Tester advantageous features.

1. the company has been engaged in testing instruments for more than ten years and has a strong after-sales service team.

2. Able to deal with all kinds of problems in time and quickly, to relieve customers of their worries.

3. spare parts are available, to solve the trouble of ordering spare parts with long delivery time.

4. provide outsourced maintenance services.

5. long-term supply of all kinds of common testing instruments.

6. Keeping up with the update of industry standards and providing timely test instruments in line with the new standards.

Previous: What kinds of wear test equipment are commonly used in the world?

N e x t : The new and upgraded UL94 Horizontal Vertical Combustion Tester for 2023