NewsInformation Center

The main factors affecting the abrasion resistance of fabrics

2023/03/27

The main factors affecting the abrasion resistance of fabrics

Fibre materials: different fibre materials have different abrasion resistance, generally speaking, natural fibres such as cotton and linen are relatively easy to wear, while synthetic fibres such as polyester and nylon are relatively more wear resistant.

The abrasion resistance of fabrics refers to the degree to which a fabric can withstand the action of forces such as friction, tearing and stretching. The main factors affecting the abrasion resistance of fabrics include the following:

Fibre materials: different fibre materials have different abrasion resistance, generally speaking, natural fibres such as cotton and linen are relatively easy to wear, while synthetic fibres such as polyester and nylon are relatively more wear resistant.

Fabric structure: the structure of the fabric also has a great impact on its wear resistance. If the same fibre material is used, the structure of plain, twill etc. is relatively thin and easily worn, while the structure of jacquard and knitted etc. is relatively denser and more resistant to wear and tear.

Chemical treatment: The finishing treatment of the fabric through chemical methods can make the surface of the fabric form a protective film, thus improving the abrasion resistance of the fabric, such as reducing the wash, pilling, adding silicon, etc.

Environment: The environment in which the fabric is used can also affect its abrasion resistance. For example, in the car seat and other places often subject to friction, the fabric is relatively easy to wear.

The above are the main factors affecting the abrasion resistance of fabrics, the degree of action of different factors may also differ, and the specific situation needs to be analysed according to the actual situation.

How do I measure the abrasion resistance of a fabric?

Measuring the abrasion resistance of fabrics requires the use of a number of specialist instruments and testing methods. The following are common methods of testing the abrasion resistance of fabrics:

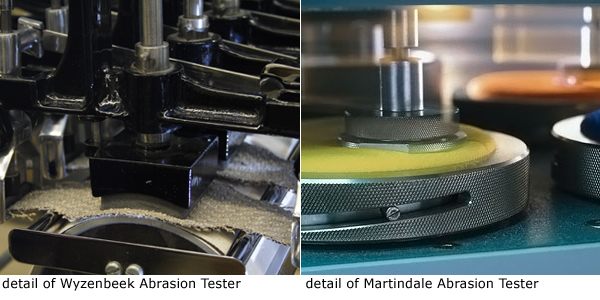

Martindale test: This is a commonly used test method and requires the use of a Martindale abrasion meter. The test is carried out by placing a fabric sample on a circular table and then applying a standardised sandpaper or flannel to the sample with a force and speed that simulates the wear and tear of everyday use. The test results are expressed in terms of the number of wear turns, i.e. how many wears it takes to penetrate the fabric.

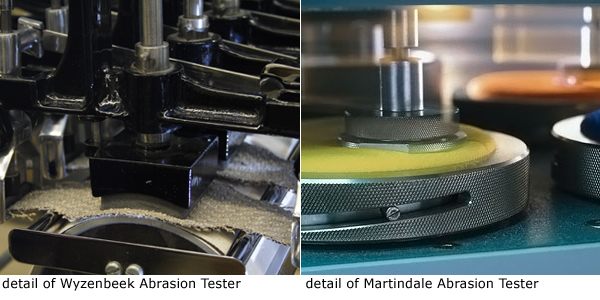

Wyzenbeek test: This is also a commonly used test method and requires the use of a Wyzenbeek abrasion meter. During the test, a fabric sample is fixed to the tester and a standardised sandpaper or flannel is applied to the sample at a force and speed that simulates the wear and tear experienced in everyday use. The test results are expressed in terms of the number of wear turns, i.e. how many wears it takes to penetrate the fabric.

Taber test: This is a more rigorous test method and requires the use of a Taber abrasion tester. During the test, a fabric sample is fixed to the test machine and a standardised abrasive wheel is applied to the sample at a force and speed that simulates the wear and tear experienced in everyday use. The test results are expressed in terms of the number of wear turns, i.e. how many wears it takes to penetrate the fabric.

The above test methods can be carried out by specialist testing institutes or by purchasing the appropriate test equipment and carrying out the test yourself. The test results can be used for fabric quality control, product performance evaluation, etc.

Previous: A discussion of common problems and solutions for fabric shrinkage testing

N e x t : 2023 China Textile and Clothing Manufacturing Forecast